www.industry-asia-pacific.com

25

'25

Written on Modified on

General Atomics Reaches New Milestone in SiC Composite Nuclear Fuel Rods

GA-EMS verified its SiGA SiC cladding joints remained gas-tight after 180 days in corrosive reactor coolant, advancing nuclear fuel safety.

www.ga.com

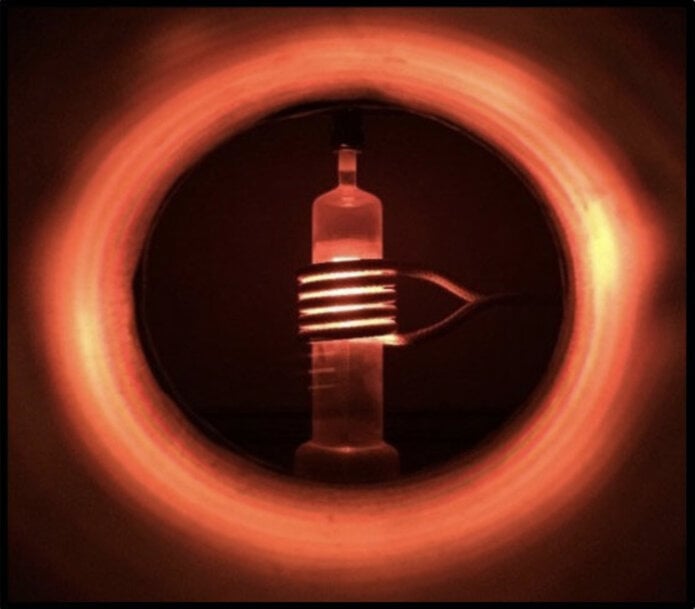

Photo taken through a furnace viewport capturing the localized induction heating process used to produce a gas tight joint at one end of a SiGA® cladding rod.

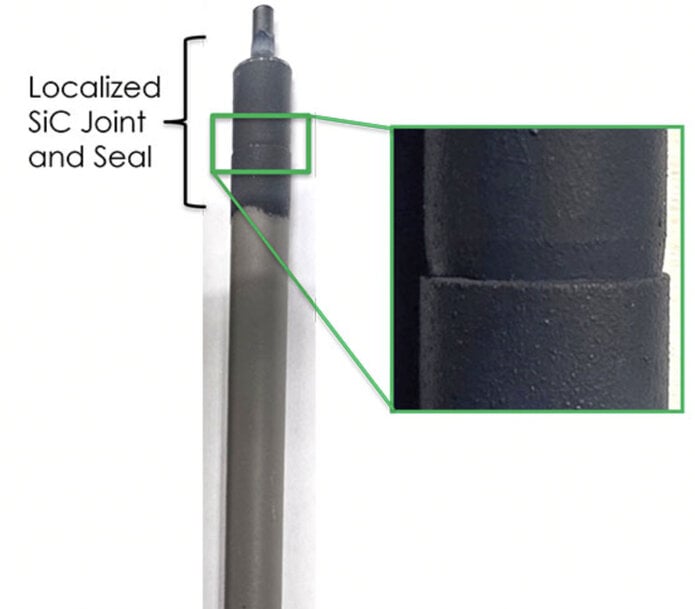

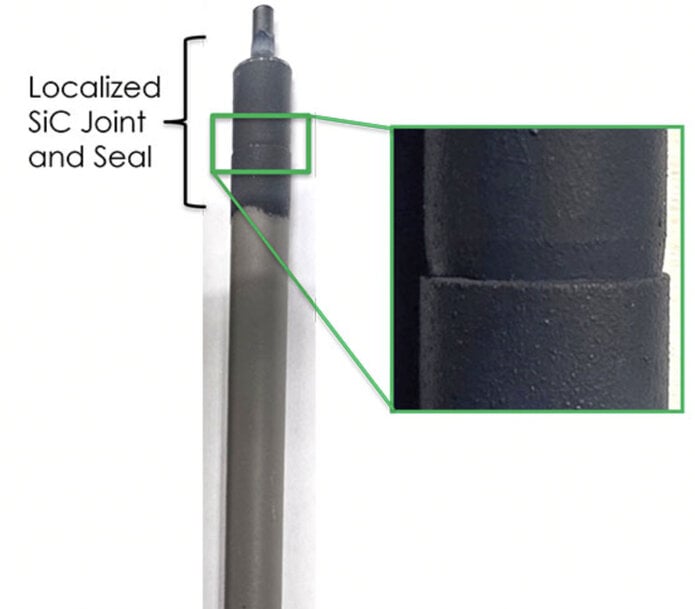

General Atomics Electromagnetic Systems (GA-EMS) announced that it has reached another significant milestone in the development and testing of its SiGA® Silicon Carbide (SiC) nuclear fuel cladding technology. Recent performance testing on GA-EMS’ patented, localized SiC joining method has shown excellent performance under the corrosive water conditions expected in the current fleet of pressurized water nuclear reactors, marking a significant step in advancing the readiness of SiGA cladding for reactor testing. SiGA is an engineered, multilayer composite cladding structure that offers high temperature performance and other operational benefits for current and future nuclear reactors.

“Our patented local joining process seals the fuel rods without exposing the nuclear fuel pellets to high temperature water,” said Scott Forney, president of GA-EMS. “Our SiC cladding and localized joining method form a complete solution to fully and safely contain the solid fuel and enable it to withstand temperatures six times greater than the expected light-water, pressurized water reactor conditions. The local SiC joining process is also proving to reduce processing time, supporting the scale-up of efficient domestic manufacturing capability to provide safe accident tolerant fuel cladding for the nuclear fleet.”

Fuel cladding is a barrier between the reactor coolant and nuclear fuel pellets and is essential to protecting the fuel while also ensuring the safety of a nuclear power plant. Fuel is stacked into cladding tubes and the ends of the tubes are joined to form hermetic seals for the fuel rods. GA-EMS’ SiGA cladding offers superior high temperature and irradiation resistance which can significantly improve the operating performance, economic efficiency, and safety of light water reactors.

SiGA® local joint verified to be gas-tight after 180 days of exposure in WEC’s reactor coolant testing facility.

“We’ve successfully verified irradiation resistance of our ceramic joints at the Oak Ridge National Laboratory High Flux Isotope Reactor test reactor,” said Dr. Christina Back, vice president of GA-EMS Nuclear Technologies and Materials. “Now, GA-EMS is working to evaluate the quality of the SiGA joints under the high temperature, high pressure, and corrosive water coolant environment expected in pressurized water reactors. We achieved a critical milestone this past month, with results confirming that joints fabricated by our local SiC joining process remained gas-tight after 180-days of exposure in Westinghouse’s reactor coolant test facility. It is very exciting to be moving to the ultimate demonstration of joint performance testing in the Advanced Test Reactor at Idaho National Laboratory in the presence of both corrosive water coolant and neutron irradiation.”

www.ga.com

General Atomics Electromagnetic Systems (GA-EMS) announced that it has reached another significant milestone in the development and testing of its SiGA® Silicon Carbide (SiC) nuclear fuel cladding technology. Recent performance testing on GA-EMS’ patented, localized SiC joining method has shown excellent performance under the corrosive water conditions expected in the current fleet of pressurized water nuclear reactors, marking a significant step in advancing the readiness of SiGA cladding for reactor testing. SiGA is an engineered, multilayer composite cladding structure that offers high temperature performance and other operational benefits for current and future nuclear reactors.

“Our patented local joining process seals the fuel rods without exposing the nuclear fuel pellets to high temperature water,” said Scott Forney, president of GA-EMS. “Our SiC cladding and localized joining method form a complete solution to fully and safely contain the solid fuel and enable it to withstand temperatures six times greater than the expected light-water, pressurized water reactor conditions. The local SiC joining process is also proving to reduce processing time, supporting the scale-up of efficient domestic manufacturing capability to provide safe accident tolerant fuel cladding for the nuclear fleet.”

Fuel cladding is a barrier between the reactor coolant and nuclear fuel pellets and is essential to protecting the fuel while also ensuring the safety of a nuclear power plant. Fuel is stacked into cladding tubes and the ends of the tubes are joined to form hermetic seals for the fuel rods. GA-EMS’ SiGA cladding offers superior high temperature and irradiation resistance which can significantly improve the operating performance, economic efficiency, and safety of light water reactors.

SiGA® local joint verified to be gas-tight after 180 days of exposure in WEC’s reactor coolant testing facility.

“We’ve successfully verified irradiation resistance of our ceramic joints at the Oak Ridge National Laboratory High Flux Isotope Reactor test reactor,” said Dr. Christina Back, vice president of GA-EMS Nuclear Technologies and Materials. “Now, GA-EMS is working to evaluate the quality of the SiGA joints under the high temperature, high pressure, and corrosive water coolant environment expected in pressurized water reactors. We achieved a critical milestone this past month, with results confirming that joints fabricated by our local SiC joining process remained gas-tight after 180-days of exposure in Westinghouse’s reactor coolant test facility. It is very exciting to be moving to the ultimate demonstration of joint performance testing in the Advanced Test Reactor at Idaho National Laboratory in the presence of both corrosive water coolant and neutron irradiation.”

www.ga.com