www.industry-asia-pacific.com

17

'24

Written on Modified on

CHINAPLAS 2024: BASF China and Autoliv China cooperate on ‘Design-for-Recycling’ polyurethanes (PU) foam technology

‘Design-for-Recycling’ technology maintains mechanical performance of recycled material even after several rounds of recycling.

Recycled material from innovative 'Design-for-recycling' PU foam technology reintroduced into foam formulation

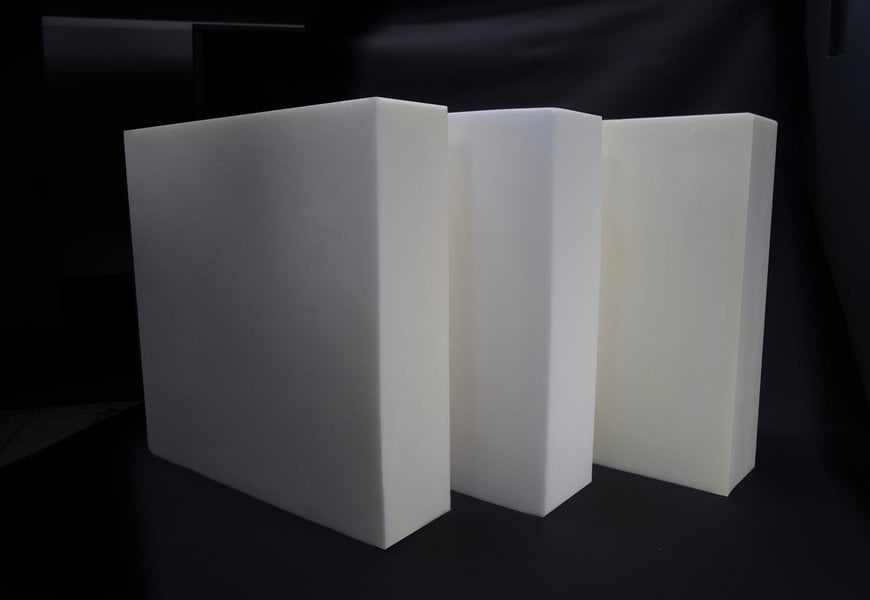

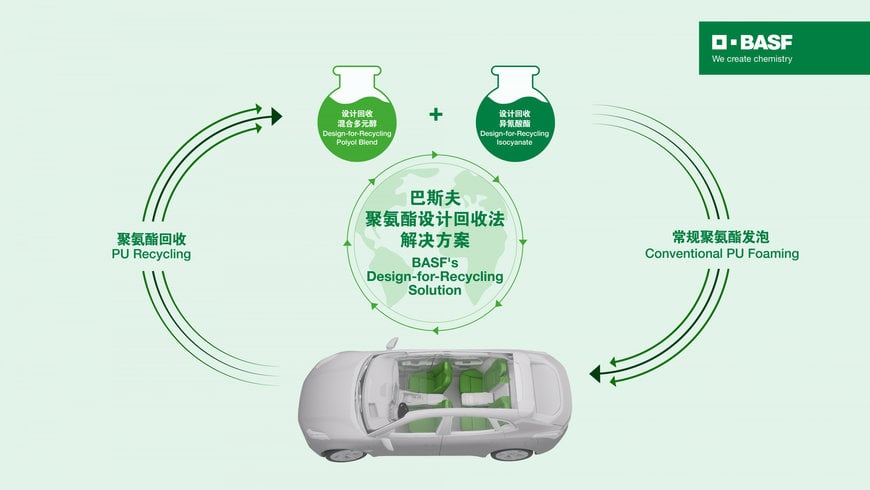

At CHINAPLAS 2024, BASF introduces an innovative ‘Design-for-Recycling’ polyurethanes (PU) foam technology enabling simplified and scalable recycling of PU foam. The recycled material in turn, can be reintroduced into the ‘Design-for-Recycling’ foam formulation. Together with Autoliv China, a leading global automotive supplier for steering wheels, BASF showcases steering wheels made with the ‘Design-for-Recycling’ foam solution containing the recycled content at CHINAPLAS 2024.

“By switching to the ‘Design-for-Recycling’ PU foam solution with recycled content, Autoliv is taking another concrete step towards circularity and reducing the environmental footprint of our products. In our line trials, we see the physical properties of the ‘Design-for-Recycling’ PU steering wheels were comparable to our current products made with conventional PU,” said Wallice Li, SCM & Sustainability Vice President from Autoliv China.

The unique ‘Design-for-Recycling’ technology specially developed by BASF was tested at the BASF pilot plant in Shanghai.

“Our ongoing partnership with Autoliv continuously demonstrates technical breakthrough and production efficiency. With the ‘Design-for-Recycling’ foam solution, we are contributing to the transformation of the PU value chain and closing the loop for many PU applications. We are driving innovation and verifying the recyclability of the ‘Design-for-Recycling’ technology – which is crucial for the development of our industry,” Silvia Mok, Vice President,

Business Management Polyurethanes Systems, Performance Materials Asia Pacific, BASF.

The amount of recycled content in the PU foam solution is currently up to 20 weightage percentage (wt%), depending on the product application. The mechanical performance of the PU foam solution with recycled content is maintained even after several recycling cycles.

Beyond steering wheels, BASF has also developed the ‘Design-for-Recycling’ foam solution for PU applications in the automotive, furniture, and footwear product segments – including automotive seating and sofa applications.

www.basf.com

At CHINAPLAS 2024, BASF introduces an innovative ‘Design-for-Recycling’ polyurethanes (PU) foam technology enabling simplified and scalable recycling of PU foam. The recycled material in turn, can be reintroduced into the ‘Design-for-Recycling’ foam formulation. Together with Autoliv China, a leading global automotive supplier for steering wheels, BASF showcases steering wheels made with the ‘Design-for-Recycling’ foam solution containing the recycled content at CHINAPLAS 2024.

“By switching to the ‘Design-for-Recycling’ PU foam solution with recycled content, Autoliv is taking another concrete step towards circularity and reducing the environmental footprint of our products. In our line trials, we see the physical properties of the ‘Design-for-Recycling’ PU steering wheels were comparable to our current products made with conventional PU,” said Wallice Li, SCM & Sustainability Vice President from Autoliv China.

The unique ‘Design-for-Recycling’ technology specially developed by BASF was tested at the BASF pilot plant in Shanghai.

“Our ongoing partnership with Autoliv continuously demonstrates technical breakthrough and production efficiency. With the ‘Design-for-Recycling’ foam solution, we are contributing to the transformation of the PU value chain and closing the loop for many PU applications. We are driving innovation and verifying the recyclability of the ‘Design-for-Recycling’ technology – which is crucial for the development of our industry,” Silvia Mok, Vice President,

Business Management Polyurethanes Systems, Performance Materials Asia Pacific, BASF.

The amount of recycled content in the PU foam solution is currently up to 20 weightage percentage (wt%), depending on the product application. The mechanical performance of the PU foam solution with recycled content is maintained even after several recycling cycles.

Beyond steering wheels, BASF has also developed the ‘Design-for-Recycling’ foam solution for PU applications in the automotive, furniture, and footwear product segments – including automotive seating and sofa applications.

www.basf.com