Omega Simulation Releases New Version of OmegaLand Integrated Environment for Dynamic

Simulation with Enterprise-scale Plant Operation Training Package. Support for additional languages and improved replication of plant behaviors.

Omega Simulation Co., Ltd., a subsidiary of Yokogawa Electric Corporation, announces the release on this date of OmegaLand V3.5, an integrated environment for dynamic simulation that plays a core role in the use of plant operation training simulators and digital twins. This new version of OmegaLand includes entirely new features as well as enhancements to existing functions.

Development Background

As awareness of the Sustainable Development Goals (SDGs) grows, there is a rising demand for solutions that will optimize energy use, reduce CO2 emissions, and improve profitability. The need to transfer the techniques and technical skills of highly experienced operators to younger personnel is a global concern, and this is particularly acute with highly difficult tasks that can result in significant financial losses of millions or tens of millions of dollars, such as plant startup and shutdown, and responding to issues and emergencies.

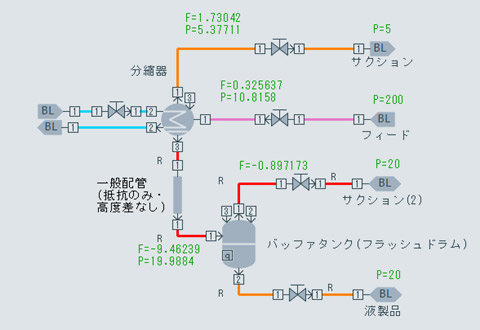

In addition to conventional operator training systems, interest is growing in the use of digital twins as a means to resolve plant issues, by recreating a physical plant in a digital space and linking an actual plant to this digital plant in real time. In this digital space, a digital twin is able to visualize a range of phenomena. This makes it possible to confirm data on process variables such as temperature, pressure, flowrate, and composition that previously may have been inaccessible, and this can help to stabilize and streamline plant operations. In order to ensure that a digital twin is making a full contribution in this capacity, the simulation must precisely reproduce the actual situation. In addition to such requirements, such solutions need to have user interfaces that support multiple languages and provide training environments that are easy to use and give multiple individuals simultaneous access to the same simulation.

Features

1. New OmegaLand Trainer Enterprise package

The OmegaLand Trainer Enterprise package includes a network function that allows the same system configuration used in simulators for education and training to be distributed, eliminating the need for settings on individual PCs. Multiple people can now share the same system configuration, allowing them to work together when tackling issues. Furthermore, the network function eases the task of upgrading this software. With this feature, the applications installed on individual client PCs are automatically upgraded whenever the application on the server is upgraded.

2. Russian, Chinese, Korean, and French language support

In addition to Japanese and English, OmegaLand now supports simulation graphics in Russian, Chinese, Korean, and French, enabling operators to perform monitoring and operation in their own language.

3. Enhanced replication of plant behaviors

While retaining the functionality that enables users to freely and intuitively create panoramic and highly realistic simulations using images captured with a 360-degree camera, plant models created using OmegaLand V3.5 now provide even more accurate replication of plant behaviors. For example, with facilities such as distillation column units and condensation units, the models now more accurately replicate the effective work performed with fluids by introducing factors such as defects in water seals and pump efficiency* of centrifugal pumps. Furthermore, additional calculation methods increase the degree of freedom in adjusting the physical characteristics of water, which enables more realistic replications of actual phenomena.

* Pump efficiency is calculated by dividing the energy from the motor by the actual output of the pump. The larger the diameter of the pump, the higher the efficiency.

Major Target Markets

Oil & gas, refining, petrochemicals, chemicals, electric power, water treatment, and beverages

Applications

- Process learning and plant operation training simulators for operators and engineers • Support for plant operations by enhancing plant visualization with a digital twin

- Process verification and analysis, instrumentation system verification and review