Siemens drives merging of physical and virtual worlds for a more flexible and sustainable industry

Under the motto "Infinite opportunities from infinite data", Siemens is demonstrating at the "Digital Enterprise Virtual Experience" at Hannover Messe 2021 how the merging of the physical and virtual worlds enables industrial enterprises to act flexibly and sustainably.

- „Infinite opportunities from infinite data“ is this year's trade fair motto

- Leveraging the full potential of data from merging the virtual and physical worlds

- "Digitalization knows no end"

- Expansion of the portfolio for edge computing in industry

As they are facing huge challenges: The Covid 19 pandemic has changed markets and requirements almost overnight. Added to this are the growing individualization and the urgent need for more sustainability. This can only be mastered with the help of digitalization and automation. Siemens brings together the data generated in this process in a continuous cycle between the virtual and physical worlds. This enables companies to better understand and use data. Traditional silos between previously separate industrial domains are breaking down and new opportunities for sustainable and flexible production are being created. This enables employees in industrial enterprises to make appropriate decisions based on data or, for example, to react a lot faster to changes such as suddenly increased resource consumption.

“The rapid development of available data in recent years makes one thing clear - digitalization knows no end. Instead, it starts an infinite loop: you collect data, and you learn from it, you take the next step," explains Cedrik Neike, member of the Managing Board of Siemens AG and CEO of Siemens Digital Industries. "In production, this creates an infinite pool of knowledge that we are far from fully leveraging. And anyone who manufactures in an industrial way can take advantage of this potential. This applies to production sites with a long history just as much as it does to completely new production sites from the very first pixel of planning onwards.

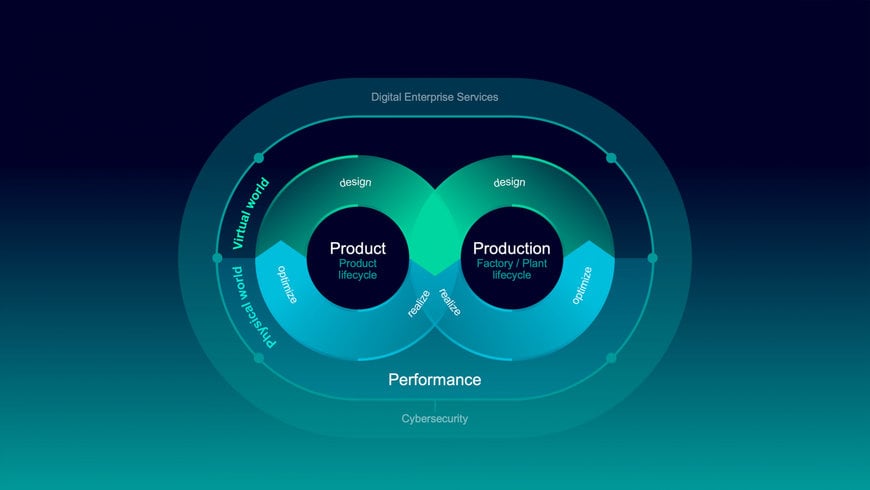

With the Digital Enterprise portfolio, Siemens supports its customers in exactly this area: With the help of the digital twin and the use of future technologies such as AI, customers can react quickly and flexibly to global challenges and, for example, adapt their products and manufacturing processes to new requirements or to save resources.

Siemens links data from the entire lifecycle of products and production, of information technology (IT) with its data analysis capabilities and operational technology (OT), and of the manufacturing level with the office level. This creates a continuous cycle for optimization. In this industrial Internet of Things, the industrial processes are modular and flexible, thus always enabling optimal adaptation of all lifecycle parameters. This also includes the factory buildings and the workflows of suppliers and logistics partners.

To ensure that data is transmitted quickly and reliably to the right place via high-performance communication networks and that all production areas can thus react immediately to changes, Siemens is continuing to drive forward cutting-edge technologies such as Industrial 5G. The ability to operate such private 5G networks enables companies to tailor them specifically to their performance, reliability, and security requirements. In Germany, companies also benefit from being able to use private 5G frequencies exclusively at their sites. As one of the key Hannover Messe exhibitors, Siemens will set up a prototype industrial 5G campus network in one of the exhibition halls. In the future, the network can be used by exhibitors during ongoing trade fairs and will be available to companies outside of trade fair times for tests and field trials.

With Industrial Edge, Siemens offers a concept in which customers can flexibly use the advantages of data processing by using edge or cloud computing, depending on the application. Siemens is also expanding its portfolio in edge computing for real-time analysis of data on-site in production and its intelligent use. In addition to the connection of Simatic and Sinumerik controllers to the Siemens Industrial Edge, the offering for the connection of drive technology is also being expanded. Drive technology is considered an important indicator of machine availability. In addition to impacting variables such as speed and torque, it also provides information for the use of edge computing as to whether the machine is running fault-free and at an optimum level within its parameters, for example in terms of energy consumption. Intelligent analysis technology can thus inform operators at an early stage when, for example, maintenance is due, or energy can be saved.

www.siemens.com