Integrated Flotation and Dewatering for Reko Diq

Metso will supply advanced beneficiation and dewatering systems to Reko Diq Mining Company to support large-scale copper-gold processing in Pakistan through a fully integrated flotation and filtration flowsheet.

www.metso.com

Metso has been awarded the remaining major contracts under a frame agreement announced in August 2024 to deliver beneficiation and dewatering equipment for the Reko Diq copper-gold project in Pakistan. The newly signed contracts are valued at approximately €70 million, with €40 million recorded in Metso’s Minerals segment order intake for the third quarter of 2025 and €30 million in the fourth quarter.

Relevance for high-throughput copper-gold processing

The Reko Diq project is designed to process large volumes of low-grade and finely disseminated ore, placing high demands on flotation efficiency, energy consumption, and water management. In such operations, circuit integration and equipment scalability are critical to achieving target recoveries while controlling operating costs.

The awarded scope covers flotation, concentrate filtration, thickening, slurry pumping, and mill servicing equipment, forming a tightly coupled beneficiation and dewatering flowsheet.

Flotation circuit design and technology selection

Metso’s delivery includes a complete flotation flowsheet combining mechanical and pneumatic flotation technologies. TankCell mechanical flotation cells will be used in the rougher and cleaner scavenger stages, where high volumetric capacity and proven hydrodynamics are required to handle large throughputs.

For ultrafine particle recovery in the cleaner scalper and recleaner stages, the circuit integrates forced-air pneumatic flotation units. This configuration targets improved selectivity and recovery efficiency for fine and complex mineral particles that are typically challenging to float using conventional mechanical cells alone.

According to Metso, combining these two flotation approaches reduces metallurgical risk while lowering capital and operating expenditure compared with fully mechanical circuits in similar low-grade applications.

Integrated regrinding and flotation

The pneumatic flotation units will operate in conjunction with high-intensity regrinding mills ordered for the project in 2024. This represents one of the first fully integrated regrinding–pneumatic flotation circuits of this scale.

The regrinding stage reduces particle size to liberate valuable minerals more effectively, while the subsequent pneumatic flotation step enhances recovery of ultrafine particles. This integrated approach is designed to improve overall metallurgical performance while reducing specific energy consumption, a key consideration in large copper-gold concentrators.

Concentrate dewatering and thickening

For concentrate filtration, Metso will supply four pressure filters along with auxiliary equipment and slurry pumps for both primary and secondary filtration stages. These systems are intended to achieve low final moisture content and stable filtration performance under variable feed conditions.

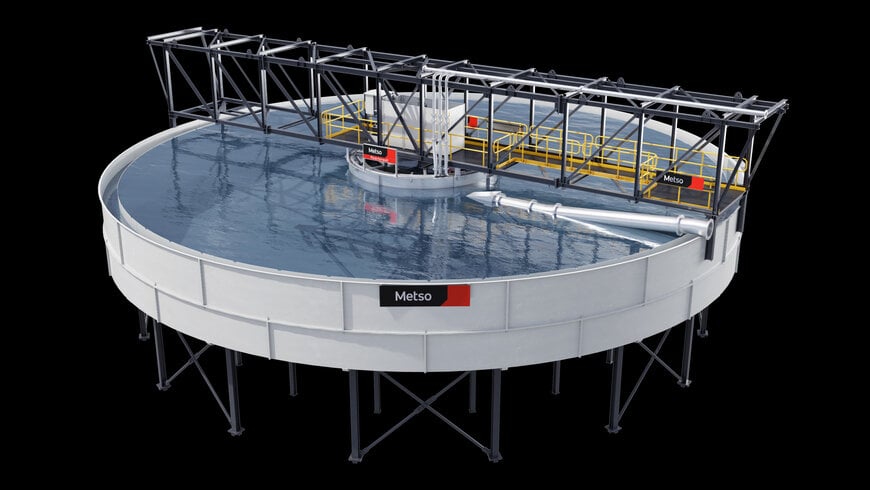

The order also includes five high-rate thickeners for different duties within the plant. Each thickener is equipped with Reactorwell technology, which enhances feed dilution, flocculation efficiency, and settling performance. This supports improved water recovery and underflow density control, contributing to more efficient water reuse across the processing plant.

Mill servicing and maintenance integration

In addition to process equipment, Metso will deliver a mill reline machine featuring automated gripping functionality and safety-oriented design. The machine will service large ball mills supplied for the project in 2024.

By providing mills, mill linings, and reline machines as an integrated package, Metso aims to ensure mechanical compatibility and simplified maintenance interfaces, reducing downtime during liner replacement operations.

Positioning within the project lifecycle

The scope awarded under this contract amendment highlights an integrated approach to beneficiation and dewatering, where flotation performance, regrinding efficiency, and water management are treated as interdependent elements rather than isolated unit operations.

For the Reko Diq project, the selected flowsheet reflects current industry practice for large, low-grade copper-gold deposits, where recovery optimisation and energy efficiency are central to long-term economic viability.

www.metso.com