Kitamura Cuts CO₂ Emissions by 90 Tons with Smart Energy Monitoring

Mitsubishi Electric’s energy-saving tech helps Kitamura Manufacturing visualize usage, automate systems, and reduce costs.

www.mitsubishielectric.com

Kitamura Manufacturing Co., Ltd. designs, manufactures, and sells aluminum truck bodies for delivery companies and other customers. Each truck body is custom-made in aluminum or stainless steel to meet specific customer requirements and installed onto a chassis supplied by a truck manufacturer. The company holds a strong market share in Japan, particularly for small 2 ton vehicles. Beyond truck bodies, Kitamura Manufacturing uses its aluminum machining expertise to produce protective housings for communications equipment, special-purpose vehicles like broadcasting and medical inspection trucks, and industrial machinery such as cleaning systems.

Kitamura Manufacturing’s main factory.

A vehicle produced at the main factory. Aluminum truck bodies are designed and manufactured to meet each customer’s requirements and installed on a standard truck chassis before delivery to the customer.

The “Limbo Van” is one of Kitamura Manufacturing’s iconic products, used by large delivery companies. The height of the loading platform can be adjusted depending on the weight of cargo or the height of the loading bay.

However, growing awareness of net-zero goals required them to take further steps.

“Since the early 2020s, customers have started asking us to report on our carbon neutrality efforts,” explains Yonemoto Hideki, General Manager of the Product Planning Division and Manager of the Carbon Neutrality Promotion Section at Kitamura Manufacturing. When companies calculate their greenhouse gas emissions to prove their environmental credentials, they are required to include figures for the entire supply chain, not just their own emissions. This means Kitamura Manufacturing’s energy-saving efforts also impacts its customers' sustainability goals.

Yonemoto Hideki - General Manager of Product Planning Division and Manager of Carbon Neutrality Promotion Section, Kitamura Manufacturing

In response, the company established a Carbon Neutrality Promotion Office, led by Yonemoto. The office set out to strengthen energy-saving measures, initially focusing on visualizing the energy usage for each building. The truck body production painting process is particularly energy-intensive, as it requires high levels of ventilation and utilizes electrodeposition treatment. This process occurs at three plants, which together account for 50–60% of the company’s total electricity consumption. Yonemoto identified these plants as a priority for targeted energy management to achieve significant savings.

A new approach to energy monitoring

To visualize energy usage for each building, Kitamura Manufacturing selected Mitsubishi Electric’s energy saving support devices.

“We considered a cloud-based system, but the cost of this would dramatically increase in proportion to the number of data measurement points. This would be too unpredictable when it came to future scalability, so instead we opted for Mitsubishi Electric’s local-based solution,” explains Inagaki Yorito of the Carbon Neutrality Promotion Section.

Inagaki Yorito - Section Chief, Carbon Neutrality Promotion Section, Kitamura Manufacturing

The company had already been using Mitsubishi Electric PLCs for control equipment at its production sites, so it decided to introduce the energy-saving support devices as well, since “everything we needed was available from Mitsubishi Electric,” says Inagaki.

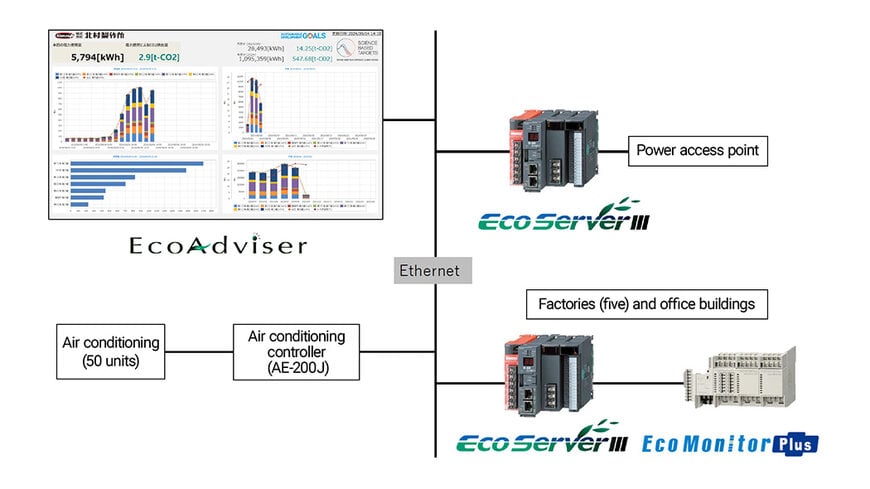

The new system was launched in June 2023. EcoWebServer III energy saving data collection servers and EcoMonitorPlus energy measuring units were installed in five sites, including the three plants with the high energy usage. The devices, connected via an Ethernet network, feed data into the EcoAdviser energy saving support software, which monitors the power consumption of each site in real time and allows energy-saving activities to be verified on a building-by-building basis.

The system introduced at Kitamura Manufacturing. The electricity usage data collected by EcoWebServer III servers in the factories and office buildings is visualized with EcoAdviser and used to automatically control air conditioning via the equipment’s controller.

Automatic and effortless energy saving

Just as the team hoped, visualizing electricity usage has significantly enhanced Kitamura Manufacturing’s energy-saving efforts. One key improvement was linking 50 office air conditioning units to the network via an AE-200J air conditioning controller. When electricity usage exceeds 90% of the set limit, the system automatically reduces operation, eliminating the need to manually turn off air conditioning units in response to a warning light.

“With the old system, sometimes the warning light would only come on when it was already approaching the limit, so it might be too late to act. The real-time link with EcoWebServer III eliminates this risk, and the air conditioning level is finely adjusted so the office staff don’t even notice the difference,” says Inagaki.

While employees understand the need to save energy, actions that feel imposed on them can be unpopular. By directly linking the air conditioning units to the energy-saving system, Kitamura Manufacturing has created a seamless, sustainable way to reduce energy use without disrupting workplace comfort.

EcoWebServer III (Upper) and EcoMonitorPlus (lower) used to capture and visualize energy usage.

Return on investment in just one year

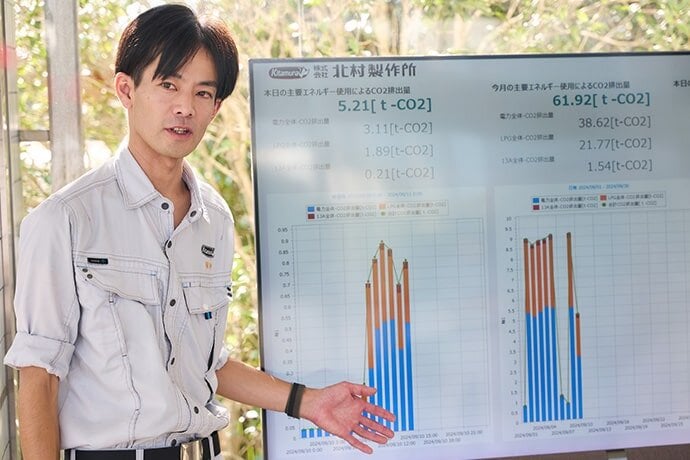

One of the key drivers for introducing energy-saving support devices was the need to provide accurate reports to business partners, which can now be created with data from EcoAdviser. As well as being monitored on a PC in the Carbon Neutrality Promotion Section, the EcoAdviser data is also displayed in the buildings’ reception area, showcasing the company’s energy saving efforts to employees and visitors.

“We can show the benefits of energy saving in terms of electricity bills, which really resonates with employees,” Yonemoto points out. The system has had a significant impact on carbon emissions and electricity costs, achieving a 90 ton reduction of CO2.

“Thanks to the improvements, we were able to recoup the cost of the system in a year,” says Inagaki.

The EcoAdviser display in the reception area showcases the company’s energy saving efforts.

Visualizing data has become a key element of Kitamura Manufacturing’s drive to become carbon neutral. As part of a company restructuring in October 2024, the Carbon Neutrality Promotion Office became the Carbon Neutrality Division and is establishing carbon neutral solutions from the product development stage.

Based on the expertise gained from the energy-saving support system, and in-line with business expansion, EcoMonitorPlus units will be installed in a new painting plant from the start of construction. The company also plans to integrate production data from existing PLCs to manage energy consumption on a per-unit basis, further enhancing efficiency and sustainability.