www.industry-asia-pacific.com

24

'16

Written on Modified on

Robust performance at peak times

Hard-wearing drive solutions for cable car stations and garages

In the Alps, tens of thousands of people take to the mountains every day, especially during the skiing season. To avoid long queues at aerial ropeway stations, failsafe equipment is indispensable. That is why Doppelmayr/Garaventa, the world leader in ropeway engineering, employs long-life, low-maintenance geared motors from NORD DRIVESYSTEMS.

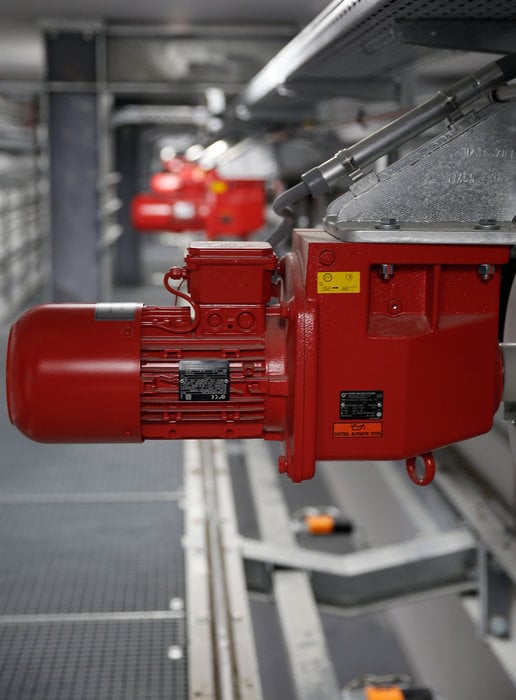

In Ischgl, in Tyrol, Austria, a so-called tricable detachable gondola lift scales the Pardatschgrat mountain. Tricable type systems feature two fixed track ropes on which the carrier travels and a circulating haul rope. With a climb of 1,251 meters, the Ischgl lift set a new world record for tricable ropeways when it went into operation. The journey takes less than 10 minutes to complete – the rated maximum speed is 7.5 m/s. Obviously, the traveling speed inside the stations has to be much lower to allow for safe disembarkation or entry. When the cabins get to the station, they are therefore detached from the haul rope and smoothly decelerated by a tire conveyor. At the passenger platform, they move at slow walking speed. Inside the station, the carrier wheels run on rails instead of track ropes. When the cabin is taken off the haul rope, friction modules make contact with the tire conveyor to ensure power transmission. Several NORD geared motors are installed here, each propelling multiple axes via a belt. The gondola lift was built by Doppelmayr, a member of the Doppelmayr/Garaventa Group, the global leader in cable car engineering and manufacturing with more than 14,600 completed projects in 89 countries. Doppelmayr has been working with the Austrian NORD subsidiary, Getriebebau NORD GmbH in Linz, since 2005. Johannes Moritzhuber, responsible for detachable gondola lifts at Doppelmayr, says: "Working with NORD, we always know we will get drives suitable for any type of installation. We choose drive solutions from NORD because they meet our expectations of maximum availability, superior safety, and excellent serviceability. NORD is extraordinarily flexible in implementing optional features. The drives are very reliable and silent, and NORD ensures fast delivery of spare parts throughout the world."

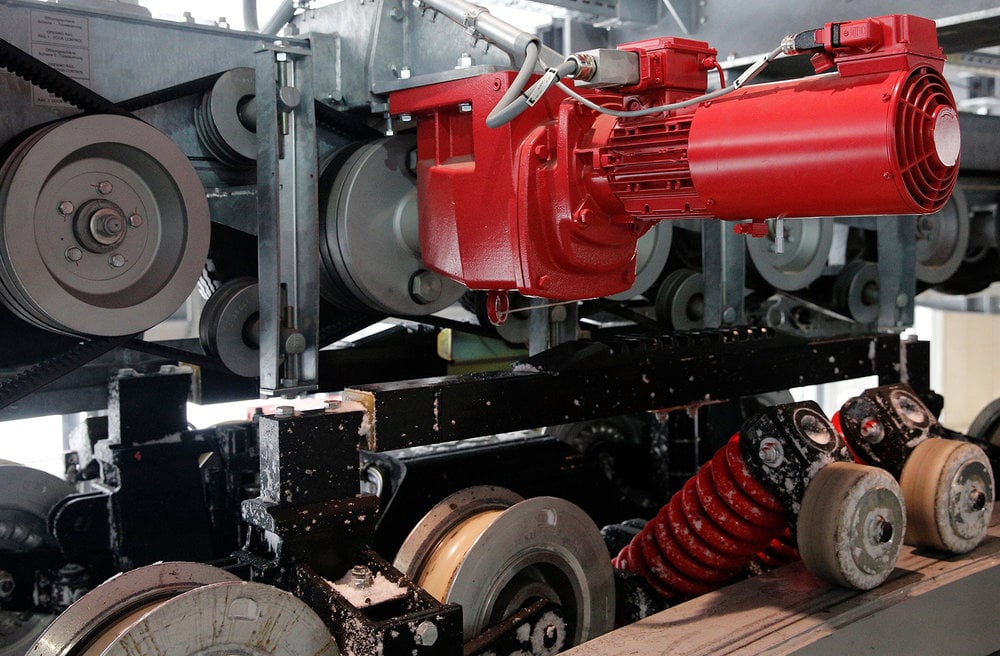

Illustration 2: NORD geared motors drive tire conveyor sections via belts

Overnight garage

Doppelmayr and NORD DRIVESYSTEMS also collaborated on the Grasjochbahn circulating monocable ropeway in the neighboring Vorarlberg. Both there and in the Tyrol project, all the cabins are kept in a garage overnight. This accommodation, which extends the service-life of the equipment, was pioneered by Doppelmayr. Initially, this required a lot of manual effort, but nowadays much of it has been automated. Both ropeways comprise a multi-track garage located under the valley stations. In the case of the Grasjochbahn, cabins are transported to the garage floor via a sloping ramp, smoothly passing from the tire conveyor to a conveyor chain. The weight is still supported by rails that run through both the station and the garage. At the Ischgl garage, the facilities are even more space-saving: the cabins travel via a vertical conveyor driven by NORD. Horizontal transport is carried out with tire conveyors. The motors are equipped with temperature sensors and encoders, and are centrally controlled.

Illustration 3: Running on overhead rails, the Grasjochbahn cabins are pulled into the garage by a conveyor chain

Illustration 4: The conveyor chain featuring catches is actuated by a NORD helical inline geared motor

Illustration 5: Parking using as little space as possible in the Grasjochbahn garage

Illustration 6: Proximity switches and NORD brake motors featuring air gap monitoring ensure that the cabins keep a safe distance from each other in the Ischgl garage

Embracing standardization

Doppelmayr introduced modularization to its various product lines many years ago. Each cable car is still individually configured to suit the geographical, geological, and climatic conditions at the installation site. However, modularization reduces the engineering and manufacturing costs and allows for standardized planning and quality assurance. The manufacturer has switched entirely to IE3 premium efficiency motors in stations, including the garages where the drives are not in continuous operation. The advanced energy efficiency class IE3 has only recently been made mandatory in Europe, and even then only for a part of all applications. Even so, Doppelmayr has opted for NORD IE3 motors due to ancillary benefits, such as a reduction of the number of variants, extended thermal and overload capacity, and suitability for worldwide deployment in countries with either 50 Hz or 60 Hz supply.

Used to special features

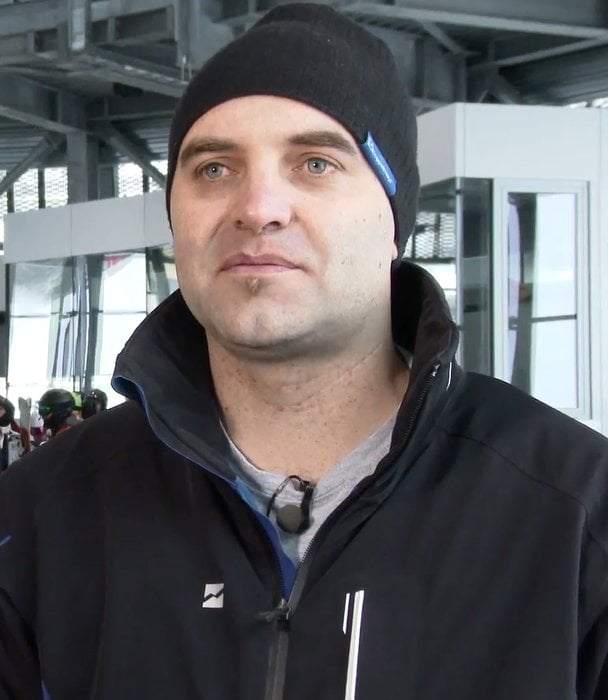

Above everything else, Doppelmayr appreciates the reliability and long service life of the drive solutions. Dietmar Fessler, who is responsible for tricable detachable gondola lifts at Doppelmayr, says: "The drives we use in aerial ropeways must operate safely at temperatures from -30 °C to + 50 °C. NORD drives easily meet this requirement." Johannes Moritzhuber, his colleague responsible for the Grasjochbahn ropeway, adds: "NORD understands the application. For instance, they have alerted us to the fact that we could increase the gearbox temperature tolerance by 5 degrees with a non-standard lubricant. In our Alpine projects, this is highly relevant and helps us achieve a long-lasting, low-maintenance drive solution." NORD offers drive options for a very wide temperature range and has implemented standstill heating, corrosion-protected brakes, and moisture protection insulation in Doppelmayr projects. The drives on the tire conveyors operate at slow speeds, which is why they are equipped with external fans: these are stronger than motor fans and can be switched on as required, thus offering an energy-efficient solution. Instead of two-pole fans, NORD has provided four-pole versions, achieving significantly lower noise emissions in the passenger area. NORD supplies the drives ready to use with plug-in power and signal connectors. In addition to simplified maintenance, this has resulted in great savings during commissioning. The drive manufacturer also implemented air gap monitoring for the brakes. A micro-switch signals when the brake disks have worn down beyond a set limit, ensuring that the brakes always operate reliably and that the brake disks are adjusted or replaced in time.

Illustration 7: Slow-running motors in the passenger area are cooled by an external fan

Illustration 8: Convenient power plugs allow for easy connection and swapping of geared motors

Illustrations 9, 10: Doppelmayr's chief engineers at the Pardatschgratbahn aerial ropeway in Ischgl, Dietmar Fessler (above), and at Grasjochbahn in St. Gallenkirch, Johannes Moritzhuber (below)