www.industry-asia-pacific.com

31

'23

Written on Modified on

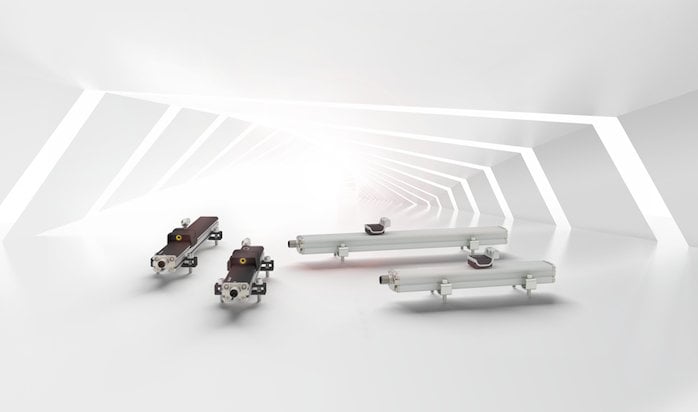

Balluff's new inductive linear measurement system: fast, precise, and flexible

The new product group BIR, Balluff is launching a new inductive and extraordinarily fast positioning system onto the market that also includes smart features.

In addition to a high level of reproducibility and a measuring frequency of at least 10 kHz, BIR also features a large, adjustable measuring range as well as a particularly compact, flat housing with small blind zones of less than 30 millimeters.

“Further advantages are high signal stability and excellent electromagnetic compatibility,” says Product Manager Andreas Blocherer.

As an innovative system, BIR (Balluff Inductive Rapid Positioning System) features a high measuring frequency of at least 10 kHz and a large, adjustable measuring range as well as a particularly compact, flat housing, among others.

BIR follows the inductive transducer system BIW. With extended technical parameters and the revised mechanics of the measuring system, Balluff is responding to the increasing market requirements.

“The new and innovative product group is ready for Balluff’s Smart Automation and Monitoring System (SAMS) as well as the Industrial Internet of Things (IIoT),” explains Blocherer. The options for continuous condition monitoring, the flexible interfaces, and the simple parameterization and diagnostics via IO-Link reduce setup and changeover times. By facilitating troubleshooting, BIR contributes to avoiding the downtime of machines and equipment.

With the revised mechanics of the measuring system, among other features, Balluff is responding to the increasing market requirements.

With its software solution, the system is used in stamping presses, industrial robots, factory automation systems, and packaging lines, among others. As an option, BIR can be configured using the Balluff Engineering Tools (BET) via IO-Link. It also enables the manufacturers of plastic injection molding and die casting machines to fill up quickly and reliably.

Thanks to precise monitoring, the injection profile can be matched exactly, making the production of even high-quality thin-walled parts possible. After filling, a gentle mold closure minimizes wear and thus extends the service life of the mold.

www.balluff.com