www.industry-asia-pacific.com

16

'22

Written on Modified on

ON-SITE FOOD FRESHNESS TESTING AT THE FRAUNHOFER INSTITUTE FOR PHOTONIC MICROSYSTEMS IPMS

Anyone who has ever ruined a cake knows that the correct identification of visually similar substances such as sugar and salt has great significance in food preparation. However, complex compositional analyses can also provide information about the quality, ripeness or freshness of products.

In the food sector, fast and reliable on-site analyses not only ensure quality, but also make an important contribution to environmental protection. Thanks to the timely detection of deteriorating freshness throughout the supply chain, food losses can be minimized. In view of shortages and rising prices of agricultural raw materials, this represents an important contribution to supplying mankind with safe, healthy and fresh food.

Freshness testing using near-infrared spectral analysis

In the field of analysis of materials in general, but especially in the case of food and its freshness, near infrared (NIR) spectral analysis is a proven method in laboratory use. Highly accurate instruments are able to provide precise information about the condition of the product at the time of measurement. However, it becomes problematic when the sample changes in the period between sampling and measurement in the laboratory, or when results are needed quickly. Many new applications could benefit from NIR spectral analysis if the systems can be miniaturized sufficiently for mobile use and made available at low cost. For this reason, the Fraunhofer Institute for Photonic Microsystems IPMS is developing ultra-small analysis devices that can even be integrated into handhelds, tablets or, in perspective, smartphones.

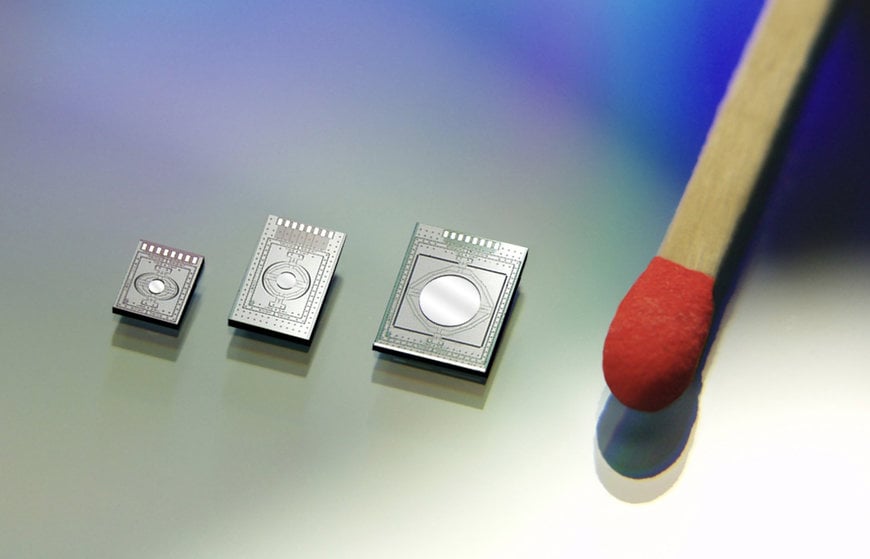

The use of micro-electromechanical systems (MEMS) enables highly compact systems that can be manufactured cost-effectively in large quantities. The quality of the measurements is competitive for many important applications despite the small size. The acquired data are chemometrically analyzed on site or online and specific characteristics are extracted from them. This makes it possible, for example, to make direct statements about the ripeness and freshness of food. Other applications such as checking correct mixing ratios in food processing, rapid incoming and outgoing goods checks or selection in recycling or reuse processes can also be served.

Current research at Fraunhofer IPMS combines a simple technology for the MEMS component with a large addressable spectral range of the system and a high degree of modularity. The core of the system is a MEMS scanning mirror, which deflects the incident collimated light beams onto a grating mounted in the system. A selection of different spectral diffraction gratings is possible, which can be optimized and used for specific applications.

Presentation of spectral analysis at the Analytica trade fair in Munich

The current demonstration system, which can also be seen at the Fraunhofer IPMS booth at the Analytica trade fair in Munich from June 21 to 24, addresses the proven spectral range from 950 nm to 1900 nm with a spectral resolution of 10 nm. Currently, the system achieves a build volume of about 2 cm³. However, further miniaturization is possible. The measurements are performed in typical arrangements depending on the sample properties, for example in transmission for liquid media or sufficiently transparent solids or in diffuse reflection for less transparent samples with sufficient scattering cross-section. The optical coupling of the spectrometer is possible as free-beam optics or via coupled fibers. In the demonstration system, the detection of white powders is shown. This could be salt, sugar, starch or flour, but numerous substances that appear visually similar can be reliably detected and assigned.

Spectral analysis provides versatile application possibilities

"In the context of evaluating food quality parameters, it has been shown that pressure and damaged spots can be detected very early on, using apples as an example, so that suitable selection allows recovery with the highest possible added value and minimizes avoidable destruction," says Dr. Heinrich Grüger, scientist at Fraunhofer IPMS. Quantitative analyses are also possible using appropriate mathematical models. Compositional analysis has been implemented to evaluate the quality of olive oil. In the context of agricultural production, target applications range from arable soil evaluation, sowing, growth and maturity to residue utilization, for example in biogas plants.

"The miniaturization of the system and the low power requirements will also enable its use in mobile applications. Integration into a host system, for example a handheld, tablet or, in the future, even a smartphone, also benefits from numerous synergy effects," Grüger continues. For example, the smartphone's processor, memory and power supply can be used. Furthermore access to database information that is important for the evaluation can be made possible. Image analysis using the camera could be used to narrow down the object to be measured and thus increase the precision of the results. For more complex measurement tasks, e.g. inhomogeneous objects, the user can be guided through the camera and display so that the measurement is performed at the intended position with the correct distance. This enables even scientific laymen to complete demanding measurement tasks quickly and reliably.

The application scenarios range, among others, for portable professional systems with correspondingly high measurement accuracy for use in the agricultural context from soil evaluation to monitoring growth to maturity evaluation for harvesting, then in the utilization of the products, i.e. storage, logistics and in distribution. At the "point of sale", the selection of goods in the display is an important application to sell goods at a reduced price for immediate consumption just before they lose freshness, instead of disposing of them the following day. On the other hand, simpler systems can be developed for the private user, for example integrated in a cell phone or as an accessory device with a wireless interface.

This will enable the consumer to take measurements on quality and freshness before purchase and make a conscious decision based on information. Especially for fruits that are still ripening after sale - a prominent example is the avocado - selection at home is supported in order to select foods that are at the peak of ripeness for consumption. Timely consumption of quickly perishable foods also makes an important contribution to minimizing food waste.

www.ipms.fraunhofer.de