www.industry-asia-pacific.com

20

'21

Written on Modified on

Siemens and TRAK Machine Tools pave the way towards Digitalization for job shops

SINUMERIK ONE digital-native CNC selected as the control of choice for new line of milling and turning production machines.

Siemens announced today that its SINUMERIK ONE CNC platform has been selected by TRAK Machine Tools (Southwestern Industries, Inc.) as the control of choice for their new VMC-series milling and TC-series turning machines. These new machine tools are intended to work in the high-volume, price-sensitive job shop market.

According to company president Steve Pinto, “TRAK wanted to partner with a large, well-established CNC leader with a global footprint for a new line of production machines, aiming to reach a new level of digitalization — one that reflected that trend in every area of life today.”

Throughout the process, Siemens employed a consulting approach, selling the value of SINUMERIK CNC and the entire Siemens portfolio of product, software, communications and cloud-based data analytics. The transition to Siemens CNC was made easier, as conventional programming and HMI with SINUMERIK ONE had the same look-and-feel as the TRAK captive control. Wanting to offer automation in its portfolio, Siemens gave TRAK Machine Tools a wide range of possibilities, with the digital-native CNC.

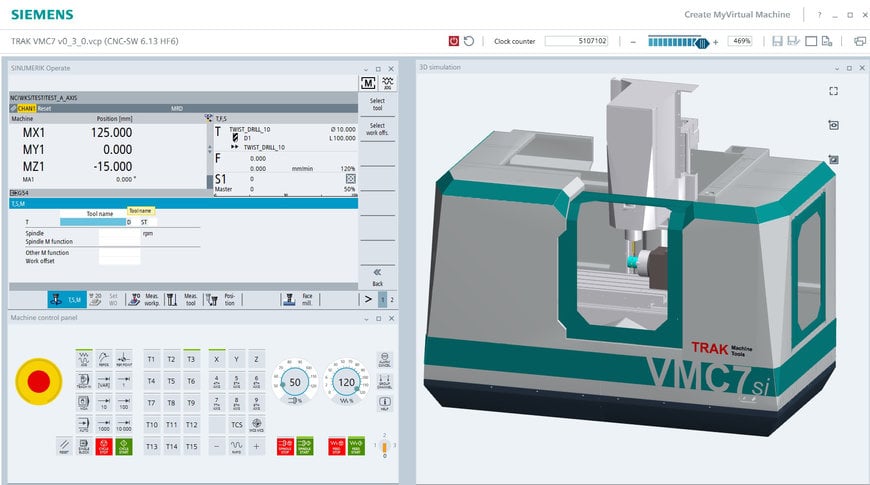

Digital Twin of the TRAK VMC7si using Create MyVirtual Machine from Siemens.

Siemens is providing user support by ramping up its standard CNC offerings for the job shop market with SINUMERIK ONE, standard PLCs for mills and lathes, custom HMI screens and it has worked closely TRAK Machine Tools for training. TRAK staff including application engineers, sales, service and dealers were offered SINUMERIK online web-based training, in-person training, and time on the machines for benchmarking and test cuts. As always, Siemens is offering spare parts, 24-hour service and a quick repair turnaround to support its products and TRAK Machine Tools’ dealers.

In the future, TRAK Machine Tools also plans to develop a 5-axis and horizontal CNC offering with SINUMERIK ONE. The company is looking to brand-label a robot to automate their CNC machine with the SINUMERIK Run MyRobotapplication, integral to the SINUMERIK ONE CNC platform.

Brian McMinn, head of the Siemens Machine Tool Systems business, observed, “This development marks the first US-based OEM that has accepted the digital-native CNC concept of SINUMERIK ONE. At every stage of development — from concept to the Digital Twin of the machine known as Create MyVirtual Machine — to the prototype and runout, Siemens has collaborated with TRAK in a very unique way. The result is an exciting line of CNC machines that will significantly impact the job shop market, almost immediately. We are proud to partner with this forward-thinking machine tool builder.”

Machine tool builders benefit from the Digital Twin by speeding up development and commissioning times to new levels of quality and efficiency.

Steve Pinto concluded, “Having found the right technology partner in Siemens, we can now offer machine technology solutions to help TRAK customers confidently take the next step into digitally-enabled production.”

For more information about SINUMERIK ONE, please visit usa.siemens.com/sinumerik-one.

www.siemens.com