www.industry-asia-pacific.com

24

'21

Written on Modified on

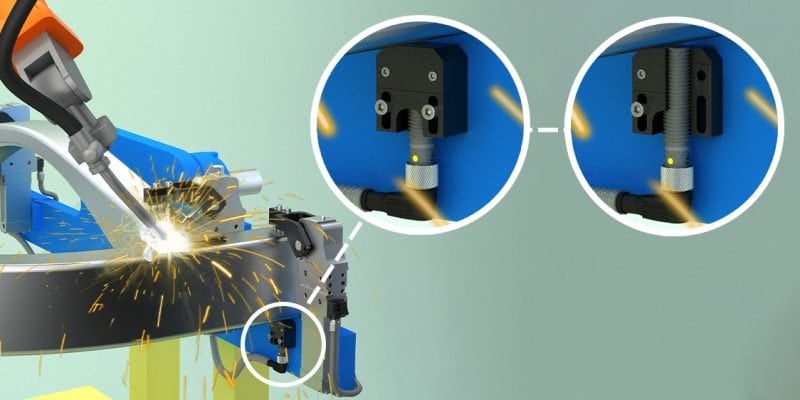

Spatter-Resistant Weld-Immune Sensors Deliver Exceptional Reliability and Extended Service Life on Automotive Chassis-Welding Lines

Automated chassis welding in the automotive sector requires synchronized operation of multiple robots, in complete safety and with minimal human intervention.

A misaligned assembly results in damage to the workpiece and potentially one or more robots, but position sensors typically suffer from build-up of welding spatter, causing rapid sensor degradation. Contrinex Weld-Immune inductive sensors with a high-performance ceramic coating are especially resistant to weld spatter and provide a robust, low-maintenance sensing solution with a best-in-class service life.

Customer benefits

- Rugged inductive sensors ensure accurate positioning of assemblies and components, eliminating welding rejects and equipment damage

- High-performance ACTIVSTONE ceramic coating prevents spatter accumulation and inhibits sensor-performance degradation

- Extended service life as ACTIVSTONE withstands frequent and aggressive cleaning regimes

- Weld-Immune sensors provide immunity to electromagnetic interference, in particular from medium-frequency weld fields

- Industry-standard IO-Link connectivity provides a single interface to the machine control system

- IO-Link configuration back-up allows plug-and-play replacement of sensors without any need for recalibration

- Proven technology ensures highly reliable operation with extended service life and minimum down-time

Specific Product Advantages

- Rugged inductive position sensors with one-piece V2A (AISI 303) stainless-steel bodies and ACTIVESTONE ceramic coating

- All external sensor surfaces, including fixing nuts and mounting brackets, are protected against spatter accumulation

- Optional spatter-resistant shrouding prevents cable damage

- Weld-Immune sensors combine optimum detection sensitivity with immunity to electromagnetic interference from welding processes

- Industry-standard IO-Link connectivity available on all Contrinex sensor product families at no extra cost

- Diverse portfolio offers exceptional range of sizes plus sensing distances up to 16 mm

- Reliable, compact vibration- and shock-resistant sensors

- Industry-standard −25°C to +70°C operating range