www.industry-asia-pacific.com

19

'20

Written on Modified on

Mitsubishi Electric’s new ACB reduces installation and maintenance stress

Targeted at commercial facilities, factories and other buildings, Mitsubishi Electric launches its new air circuit breakers (ACBs) with a breaking capacity of up to 50kA. The new range, called "AE V Series C-class", offers a number of built-in features that reduce the need for multiple additional accessories. For example, when utilizing the built-in solenoid for remote operation the traditional motor charging devices and closing coils can be dispensed with as the breaker only requires an appropriately matched shunt trip device. This helps to eliminate additional parts that were previously required to achieve remote operation.

User friendly breaker design reduces panel maintenance stress.

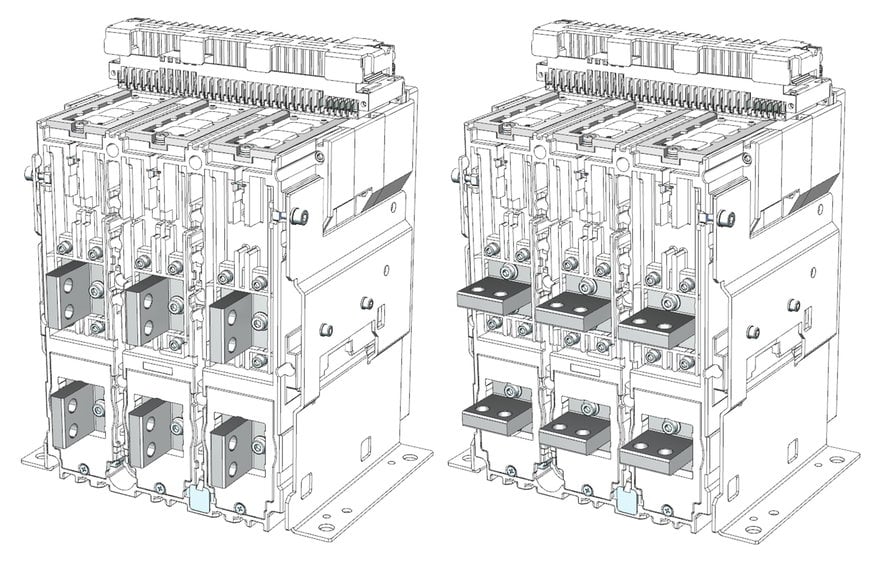

Installation, use and maintenance represent the whole life cycle of an air circuit breaker. At each stage the AE V Series C-class breakers have been designed to bring additional benefits to users. At installation the universal terminals make wiring easier and more flexible, which in turn reduces unnecessary time wastage and streamlines stock holding.

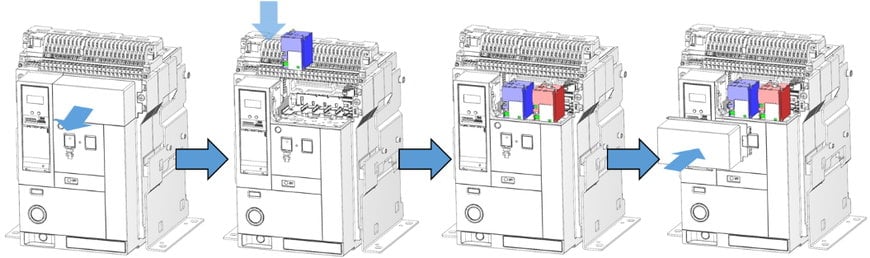

The overall unit design consolidates many points within the main breaker frame, reducing the number of required external devices. When options are required such as a shunt trip device or an under voltage trip device they can be quickly fitted into slots accessible by panel builders from the front of the breaker, making the panel quick to construct but also aiding maintenance as the accessories can be checked simply by removing the front cover. Also owing to the solenoid, maintenance processes can be reduced by 30% over existing models, helping to reduce both the maintenance time and time the breaker is offline. The new design also includes a built-in drawout handle on the front, making maintenance work easier.

Furthermore, as the C-class can be "charged" electronically via the solenoid the charging power can be reduced by 88% compared to spring-charge type ACBs using motor charging devices and closing coils. In addition, charging noise can also be kept extremely low, again, providing increased benefit in maintenance.

As already noted the optimal design removes unnecessary accessories, reducing the number of potential failure points which, during the use life of the breaker, contributes to greater breaker durability.

ACBs that do the job today and into the future.

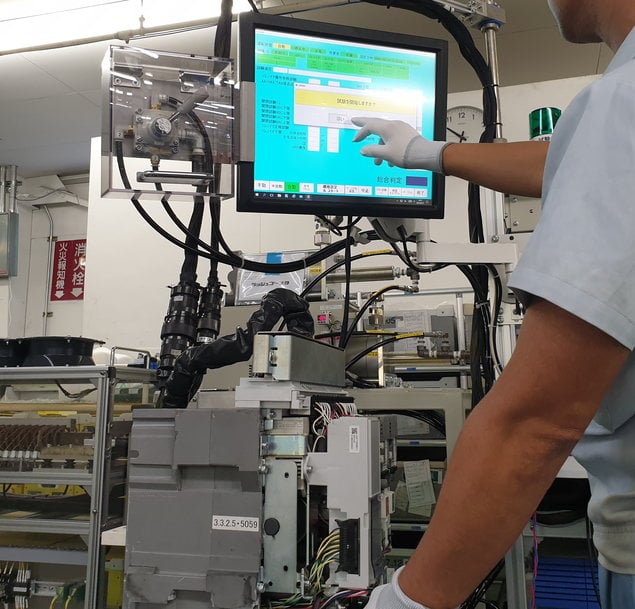

With over 86 years of breaker design, manufacture and test, quality is a very important criteria for Mitsubishi Electric's air circuit breakers, and the AE V Series C-class is no exception; from operational design through to maintenance considerations and final standards compliance meticulous attention is applied to all aspects. The company’s commitment to quality is embodied in its tough testing regime, from initial design tests to verify the design performance to its on-going quality and functional test-all policies for every circuit breaker it makes. With sales in over 100 countries, high quality products are universally required.

Going forward, additional high-end models in the AE V series will be released in the future. They bring the promise of network connectivity supporting users as they integrate power management into their Smart Factories and Digital Manufacturing processes. Furthermore, IoT functions and the possibility to consider new ways of access, including wireless monitoring by the users’ smart devices such as tablets and smartphones are also being planned.