www.industry-asia-pacific.com

01

'20

Written on Modified on

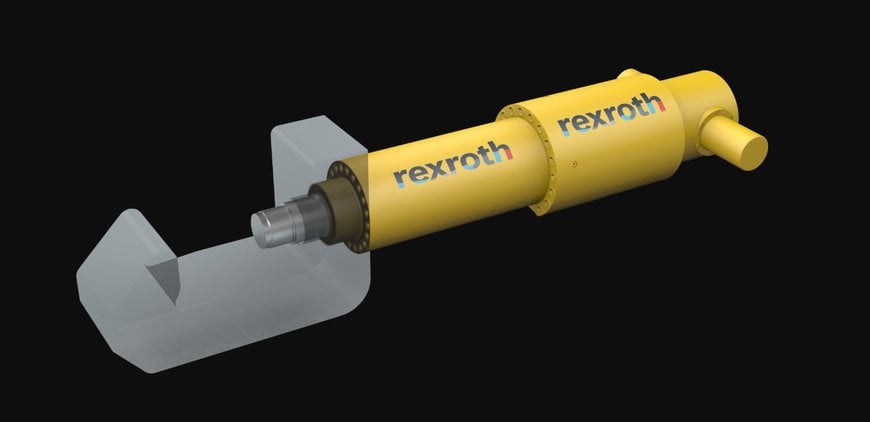

The new Subsea Clamping Cylinder takes into account the complete life cycle of riser systems: whether it be transport and storage on the seabed, commissioning and reliable use, or removal and reuse

With the innovative Subsea Clamping Cylinder for fully automatic Bend Stiffener Connectors (BSCs), Bosch Rexroth is setting new standards in term of safety, reliability and economy. The system is designed for use for up to 25 years and is impressive with its high clamping forces, powerless holding operation, and easy installation with no need for manual work by divers.

The patented automation solution withstands forces of up to 120 tons per clamping cylinder. A proven cushioning mechanism absorbs vibrations and distributes the load across a number of cylinders within the system. This prevents material fatigue and premature wear with a predefined clamping force. The integrated clamping unit allows straightforward, reliable actuation during commissioning and removal – even after long periods of use.

Bend Stiffener Connectors (BSCs) protect riser systems against premature material fatigue coming from movements such as those caused by waves. This helps protect valuable investments and increase the availability and productivity of the offshore equipment. In a fully automatic BSC, a number of Rexroth clamping cylinders are used as a system.

The patented automation solution reliably protects riser systems against bending loads and allows a secure and economical holding operation. It is designed for use for up to 25 years and no manual diving work is necessary during installation and removal. Holding operation requires no power – a hydraulic supply is only required for the initial clamping and subsequent removal. Bosch Rexroth offers an optional integrated hydraulic power unit (HPU) with electrical control systems for this purpose.

While the rated force is being set hydraulically, a spring in the cylinder is tensioned and fixed using a safety lock unit. This allows the clamping force to be maintained over the entire operating time in a purely mechanical manner, with no need for a continuous hydraulic or electrical power supply.

Thanks to the innovative combination of flexible mechanical and hydraulic force components, the loads which act in all six degrees of freedom are automatically distributed to the Subsea Clamping Cylinders installed in the system. Each individual cylinder can withstand up to 120 tons. Compared to conventional solutions, this flexible load distribution allows a much longer operating life and higher system availability.

A further advantage: the robust design of the Subsea Clamping Cylinders takes into account the entire usage cycle. Until the system is installed, it can be stored under water at a depth of up to 3,000 meters for a period of two years. The clamping unit can be hydraulically released and controlled easily, safely and reliably for removal or for further use.

The Subsea Clamping Cylinders can be used in numerous different clamping applications – not just in a marine or offshore setting but on land too.

www.boschrexroth.com