www.industry-asia-pacific.com

14

'19

Written on Modified on

3D Systems’ Cimatron® CAD/CAM Software Boosts Productivity and Improves Efficiencies for Tool Makers

HARTING Applied Technologies and VMR GmbH & Co. KG rely on 3D Systems’ Cimatron integrated CAD/CAM software to enhance data integration through the entire mold-making process, improve tools quality, reduced scrap and accelerate delivery time.

3D Systems (NYSE:DDD) has announced that two leading German industrial tool makers are using Cimatron® integrated CAD/CAM software by 3D Systems to overcome production challenges faster and more successfully.

Cimatron software, a dedicated design and manufacturing solution for tooling, is drawing renewed interest from customers in Germany because of its ability to design and deliver molds faster, maintain data integrity between design and manufacturing, and its outstanding electrode design and EDM programming application.

“At 3D Systems, we are constantly looking for innovative ways to help our customers maintain a competitive edge – and address market demands to produce better tools, in a shorter time frame, with lower costs. It’s great to see the success that both HARTING Applied Technologies and VMR have had using Cimatron,” commented Radhika Krishnan, senior vice president, software and healthcare solutions, 3D Systems.

HARTING Applied Technologies Improves Tool Quality, Reduces Scrap and Delivers Molds Faster with Cimatron

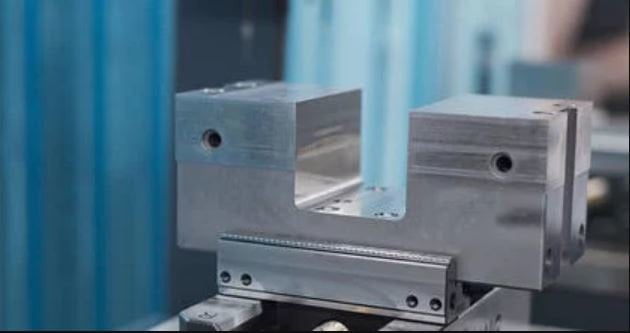

HARTING Applied Technologies, headquartered in Espelkamp, Germany, is a specialist in sophisticated toolmaking. The company develops, designs and produces injection molds, die-casting molds, stamping and bending dies, and special machines.

Following a phased implementation of Cimatron, all application areas at HARTING are now served by this dedicated, integrated CAD/CAM software. This has helped HARTING to enhance data integration through the entire mold-making process, resulting in improved production quality and efficiency with decreased lead times, reduced scrap and improved tool quality.

“Rolling out Cimatron enabled us to quickly resolve our substantial problems in the EDM area, which we had been combating for 12 years. With the implementation of Cimatron, we achieved data and process integration in the entire mold-making process, which is a key advantage for us,” said Andreas Weiß, production manager, HARTING Applied Technologies.

VMR Achieves Fast, Efficient Prototyping with Cimatron

VMR GmbH & Co. KG, located in Mönchweiler, Germany, offers a broad range of manufacturing technologies – supporting its customers with design and NC programming, production and assembly, as well as providing customized mold design and optimization.

VMR uses Cimatron integrated CAD/CAM software to efficiently, cost-effectively design and manufacture prototypes and short manufacturing runs. The use of this software has helped the company reduce electrode design and manufacturing time by 70%. Additionally, VMR is now able to operate their milling and EDM machines at full capacity to produce 10,000 graphite electrodes per year, at a rate of roughly 50 per day.

“In our business, speed is crucial,” said VMR’s CEO, Thomas Viebrans. “Each day brings different customers and different challenges that require an extremely flexible, efficient CAD/CAM system. Cimatron has enabled us to maximize our ROI by increasing efficiency and productivity through automation, accelerating on-boarding time for new employees, and completing more orders.”

3D Systems announced on August 29 that Cimatron 15, which enables toolmakers to deliver exceptionally high-quality tools, faster with new and enhanced capabilities, will be generally available in late Q4 of 2019.

www.3dsystems.com