www.industry-asia-pacific.com

11

'19

Written on Modified on

Hengst industrial filters meet the strictest global standards

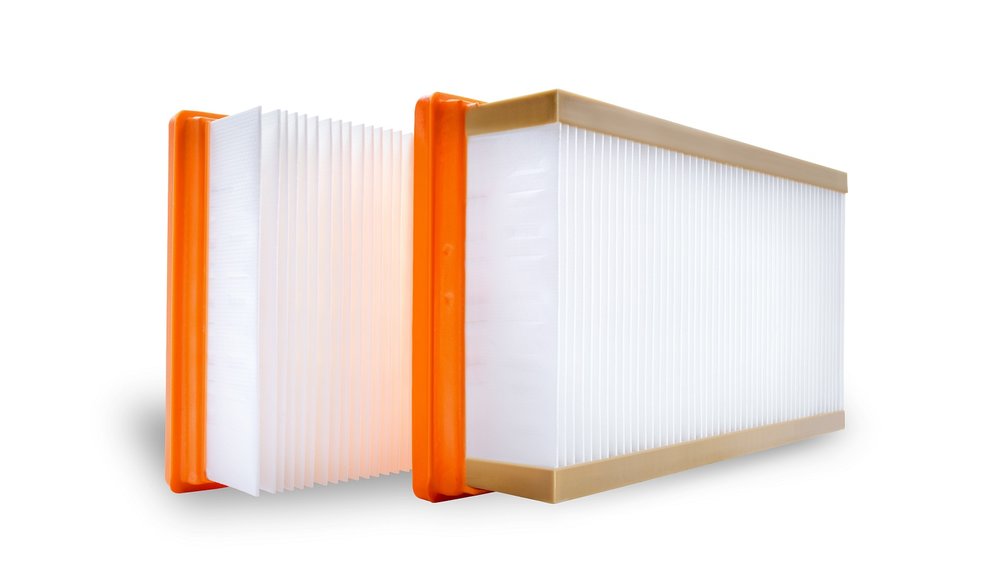

Hengst Filtration offers their customers industrial filter solutions that are tailored to meet the specific regulations applicable in the respective country of use.

More rigorous limits

The United States in 2016 introduced stricter limits on the protection of persons handling silicate dusts that deviate from the European provisions as set out in standard EN 60335-2-69. OSHA has spelled out the applicable requirements in the stipulations of the 1910.1053 – Occupational Safety and Health Standards and 1926.1153 – Safety and Health Regulations for Construction.

These standards mandate that the filters used must satisfy the requirements levied on HEPA filters (separation performance 99.97 % at 0.3 µm). The vacuum used furthermore needs to be equipped with a cyclone pre-separator or a filter insert that is cleanable.

A new combination secures compliance

Newly developed by Hengst, the filter can be cleaned and offers a filtering efficiency of 99.97 % for a particle size of 0.3 µm, thus meeting the requirements established by OSHA. Until now, fiberglass media embodied the state of the art in HEPA filter technology. However, these media are merely designed as classic depth filtration media.

This means that the hazardous substances are retained on the interior of the medium, where they cannot be cleaned off at all or only to a limited extent. This is why Hengst has selected a combination of a special PTFE membrane and a matching backing material for their new cleanable filter. Filtration is provided by the filtered dust settling on the surface of the filter medium in the form of a filter cake, which can subsequently be removed easily using, for instance, a pressure pulse.

Category H filters for Europe

Launched last year to cater to the European market, Hengst’s category H filter fulfills the strict requirements specified for IFA hazard category H (as per EN 60335-2-69) even when subjected to high inflow velocities and can be cleaned as well.

Filters categorized in class H are required to deliver a retention factor of 99.995 % and have been made mandatory for the expulsion of hazardous dust particles (carcinogenic and pathogenic) in workplace environments with limits < 0.1 mg/m³. Suitable vacuums are used for these types of dust if the purified air is supposed to be channeled back into the workroom.

Hengst Filtration offers their customers industrial filter solutions that are tailored to meet the specific regulations applicable in the respective country of use. Last year, the company already unveiled a cleanable industrial filter that is in compliance with European hazard category H, as established by the Institute for Occupational Safety and Health of the German Social Accident Insurance, or IFA.

The leading specialist in filtration and fluid management is now introducing a filter designed for industrial wet and dry vacuums that conforms to the latest requirements imposed on HEPA filters by the Occupational Safety and Health Administration (OSHA) in the United States.

More rigorous limits

The United States in 2016 introduced stricter limits on the protection of persons handling silicate dusts that deviate from the European provisions as set out in standard EN 60335-2-69. OSHA has spelled out the applicable requirements in the stipulations of the 1910.1053 – Occupational Safety and Health Standards and 1926.1153 – Safety and Health Regulations for Construction.

These standards mandate that the filters used must satisfy the requirements levied on HEPA filters (separation performance 99.97 % at 0.3 µm). The vacuum used furthermore needs to be equipped with a cyclone pre-separator or a filter insert that is cleanable.

A new combination secures compliance

Newly developed by Hengst, the filter can be cleaned and offers a filtering efficiency of 99.97 % for a particle size of 0.3 µm, thus meeting the requirements established by OSHA. Until now, fiberglass media embodied the state of the art in HEPA filter technology. However, these media are merely designed as classic depth filtration media.

This means that the hazardous substances are retained on the interior of the medium, where they cannot be cleaned off at all or only to a limited extent. This is why Hengst has selected a combination of a special PTFE membrane and a matching backing material for their new cleanable filter. Filtration is provided by the filtered dust settling on the surface of the filter medium in the form of a filter cake, which can subsequently be removed easily using, for instance, a pressure pulse.

Category H filters for Europe

Launched last year to cater to the European market, Hengst’s category H filter fulfills the strict requirements specified for IFA hazard category H (as per EN 60335-2-69) even when subjected to high inflow velocities and can be cleaned as well.

Filters categorized in class H are required to deliver a retention factor of 99.995 % and have been made mandatory for the expulsion of hazardous dust particles (carcinogenic and pathogenic) in workplace environments with limits < 0.1 mg/m³. Suitable vacuums are used for these types of dust if the purified air is supposed to be channeled back into the workroom.

www.hengst.com