www.industry-asia-pacific.com

23

'19

Written on Modified on

Problem solver packs a punch with high material removal rates

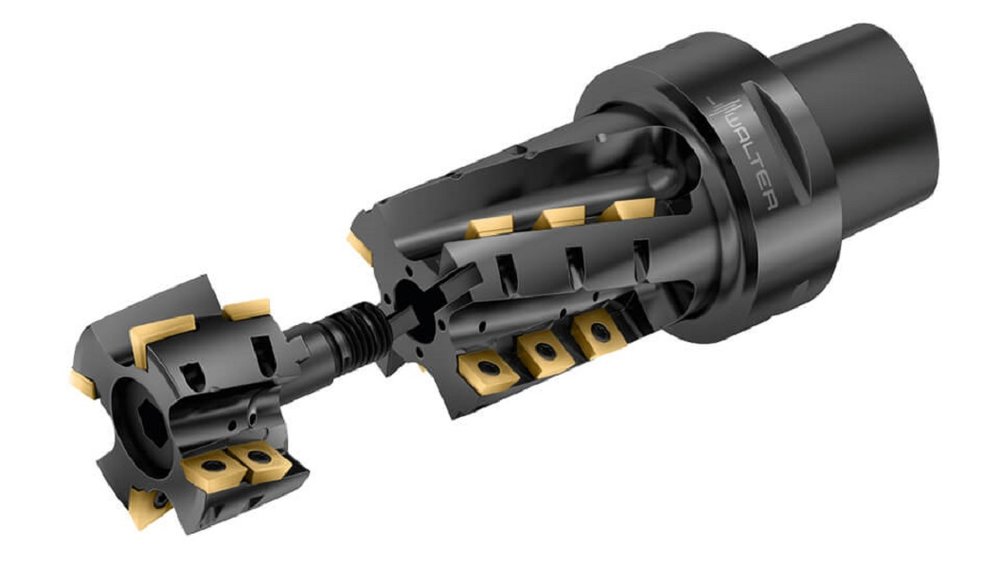

Walter AG is using its half effective M4258 porcupine milling cutter for shoulder and slot milling to combine the benefits of a milling body with those of indexable inserts.

The positive-locking connected interfaces in the front piece ensure that precision is maintained. Good chip clearance and internal cooling ensure high process reliability and safe chip evacuation. Walter Capto™ C6 and C8 have been chosen as interfaces to the machine. These are tried and tested, especially in highly universal applications and with any kind of modular machining tool.

The indexable inserts used continue the trend in saving tool costs. The M4258 is equipped with M4000 system inserts: Square and rhombic with four or two cutting edges – and can be used not only in porcupine milling cutters, but also in face, shoulder, chamfer and T-slot milling cutters. Diverse geometries, such as the D51 anti-vibration geometry, allow the milling cutter to be used in difficult conditions.

Tiger·tec® Gold inserts are additionally available on request – these increase the tool life further. M4258 milling cutter and M4000 system inserts: A solution which reduces storage and procurement costs while simultaneously conserving resources. This is because the entire milling cutter (including body) is manufactured with CO2 compensation.

Suitable for practically all materials, such as cast iron, steel, stainless steels and materials with difficult cutting properties. The modular porcupine milling cutter from Walter is available in diameters of 50–80 mm. For anyone machining with high material removal rates in unfavourable conditions.

www.walter-tools.com