www.industry-asia-pacific.com

19

'17

Written on Modified on

Laser Marker: SAMAC A win-win partnership for quality assemblies

Thanks also to the quality of KEYENCE components and service, Samac, a company in the province of Brescia which is specialized in the development of assembly and testing automation solutions, is increasingly developing its activities towards the international markets.

“Our customers operate mainly in the automotive sector – says Christian Vaglia, Samac's Marketing Engineer – a highly competitive sector where flexible and, at the same time, high-performance solutions are required to automate the components' assembly and testing processes”.

“Thanks also to the development of solutions in line with the Industry 4.0 paradigm, we are presently considered among the most dynamic and active companies on the market. We are growing at a very fast pace and a part of this success is certainly linked to the collaboration with our suppliers, among which KEYENCE stands out”, adds Mr Vaglia. “KEYENCE is a quality brand known on the market and allows us to use cutting-edge products in our systems, giving us an edge over our competitors. This is a value which is also acknowledged by our customers”.

The encounter with quality

Samac has long decided to use only the highest quality components for its machines. “We don't cut corners when it comes to quality”, says Michele Giacoboni, Samac's purchasing manager.

The use of KEYENCE components and systems within the machines and units developed by Samac is contributing to the company's technological growth. “By using quality tools such as those proposed by KEYENCE, we have managed to obtain an increasing number of orders, especially on international markets. Indeed, at times, our offer exceeds customer demands in terms of quality and performance”, continues Mr Vaglia.

The KEYENCE one-stop-shop

“Automotive sector characteristics and those of the other sectors for which we work, require us to choose suppliers with a full range and who are ready to quickly meet our requests: KEYENCE has one of the most complete catalogues on the market, consisting exclusively of products of the highest quality and which are highly innovative”, explains Mr Giacoboni. “The completeness of the range allows us to use the KEYENCE catalogue as a one-stop-shop, a single reference where we find everything we need in the areas of reference”.

Furthermore, with KEYENCE, Samac can count on fast delivery times for all products, “even for the more expensive ones that usually require rather long timings”, emphasises Mr Giacoboni.

However, the concept of reactivity, within the partnership with KEYENCE, goes further: “It often happens that our customers modify the characteristics required of the machine along the way. This is why it is very important for us to turn to suppliers who allow us to keep acceptable development and delivery times even in case of changes”, concludes Mr Giacoboni.

Service and support for growth

In addition to the responsiveness and completeness of the range, another factor was fundamental for Samac: global support. “By using KEYENCE products, we not only have the opportunity to choose high quality and technical components, but also to benefit from a global assistance service which is of crucial importance to us, as we are increasingly working with customers not only in Europe, but also in China and the United States”, explains Mr Giacoboni. “Moreover, in the event of breakdowns, KEYENCE is able to provide us with a free replacement forklift within 24/48 hours throughout Europe”.

The support provided by KEYENCE also extends to the commercial level. “In a particularly positive period like this, we are very appreciative of KEYENCE's willingness to support volume growth: it is a partner that is demonstrating its ability to put forward a long-term strategy”.

A bouquet of technologies

“Our collaboration with KEYENCE began over 10 years ago. Over the years we have used with satisfaction many of the products showcased in the company's catalogue”, explains Marco Colbrelli, Samac's technical director.

In order to read and verify the readability and consistency of mono and two-dimensional codes, Samac uses the readers of the SR-750 and SR-1000 series. “We will soon be testing the new SR-2000”, states Mr Colbrelli.

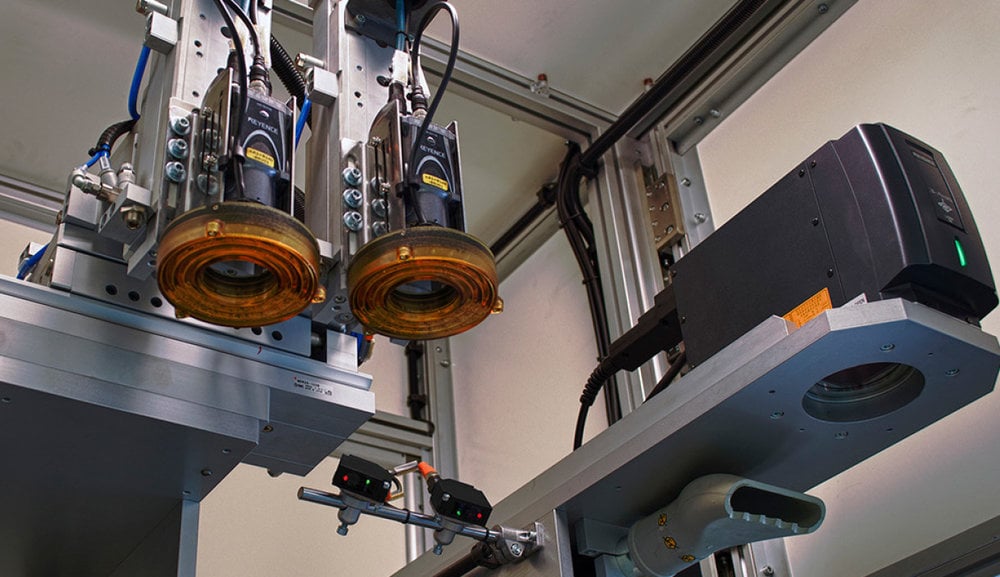

Whereas, the XG-7000 series high-speed image processing systems, the XG-8000 series multi camera systems or the CV-X series easy-to-configure systems are used in control applications of shape, size and other surface characteristics.

For less complex applications, the smart cameras of the Series IV are used instead, such as the IV500MA.

Laser marking systems are another important component for Samac machines, which enable the engraving of all the data necessary for traceability on the available product. “With its systems of the MD-X and MD-F Series, which offer wattage between 13W and 50W, KEYENCE has provided us with quality products able to respond to requests that vary according to the material, the time available for the engraving operation, the necessary depth”, explains Mr Colbrelli. “They are also 3D products which are therefore able to perform markings on different surfaces, even inclined ones without moving the head. This grants us a great deal of flexibility – a vital factor in a sector such as the automotive one in which the systems must be able to adapt to always different products”.

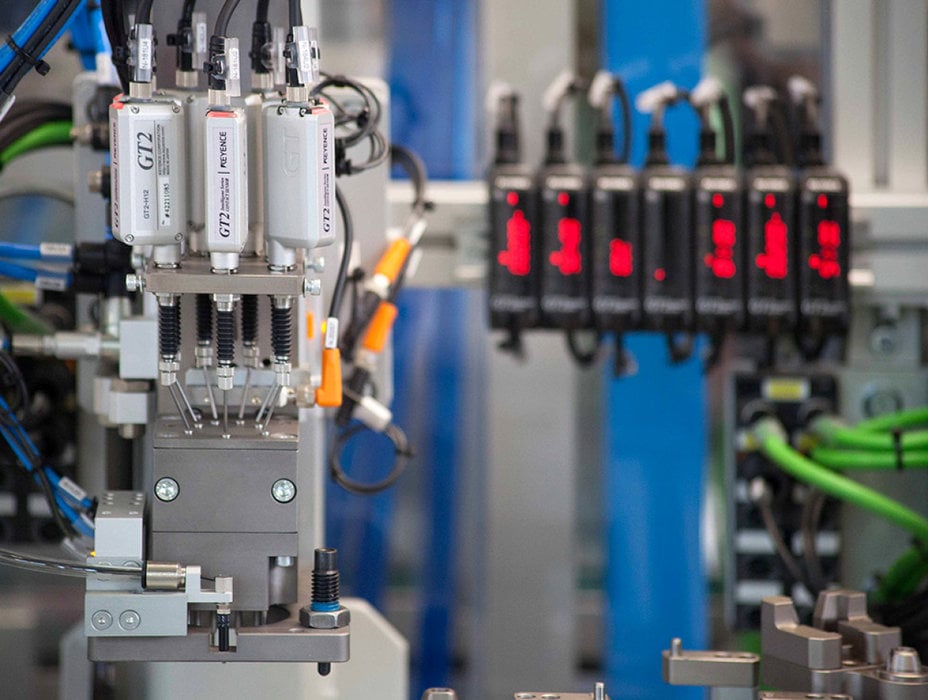

For dimensional control (thickness, correct assembly, correct positioning, correct tightening, etc.), Samac adopts the multi-function laser micrometres of the IG Series and the IB laser barrage sensors, while for the contact measurement operations it uses the sensors of the GT2 Series. Other products used include non-contact 2D profilometres for profile measurement and for pit presence and size monitoring, safety light curtains of various types and sizes for harsh, clean environments and photoelectric sensors for detecting the presence of the part.

www.keyence.it/samac