www.industry-asia-pacific.com

04

'25

Written on Modified on

How Tier-One Suppliers Adapt to EVs: Strategies and Shifts in a Fast-Evolving Landscape

As electric vehicles shift from niche to norm, Tier-One automotive suppliers are in the midst of a profound transformation, writes K.A. Gerardino.

As electric vehicles (EVs) shift from niche to norm, Tier-One automotive suppliers—those that deliver directly to Original Equipment Manufacturers (OEMs)—are in the midst of a profound transformation. Once anchored in the legacy of internal combustion engine (ICE) systems, these suppliers are now racing to keep pace with an automotive industry where electrification, software, and sustainability define competitive advantage.

According to BloombergNEF, global EV sales are projected to surpass 20 million units in 2025. This dramatic acceleration in EV adoption is triggering strategic reinventions across the supplier base. From product portfolio shifts and acquisitions to localization and full software integration, Tier-One suppliers are reinventing their core business models to stay viable in the rapidly evolving automotive landscape.

Pivoting Product Portfolios Toward Electrification

One of the most immediate and visible shifts among Tier-One suppliers is the transformation of their product portfolios. The traditional core of many suppliers—components such as turbochargers, exhaust systems, and fuel injection units—is being phased out. These parts are either irrelevant or dramatically reengineered for EVs, leading Tier-One suppliers to pivot towards technologies better suited for electrified drivetrains.

Major players such as Bosch, Magna, Denso, and Continental have announced multi-billion-dollar investments to expand capabilities in e-motors, power electronics, thermal management systems, battery management systems (BMS), and advanced driver-assistance systems (ADAS). Bosch, for instance, opened a state-of-the-art semiconductor plant in Dresden, Germany, dedicated to producing silicon carbide (SiC) chips optimized for EV powertrains. SiC semiconductors offer higher efficiency and lower heat generation, which translates to improved battery range and durability.

Similarly, Magna launched a joint venture in India in early 2025 to build integrated e-drive systems aimed at mass-market EVs in Asia. The company recognizes that the future of electrification will require scalable, modular systems adaptable to a wide array of OEM platforms.

Denso has introduced a new range of power modules and inverter systems specifically engineered for EVs, with production facilities ramping up in Japan, Thailand, and the United States. The company’s next-generation BMS technology also incorporates AI-based predictive analytics to improve battery longevity and performance.

Continental, beyond its investments in ADAS, is also developing 800V power electronics platforms to support ultra-fast charging infrastructure. These developments are key as EV manufacturers push to reduce charging times and improve vehicle uptime.

Aptiv has expanded its product line to include high-voltage cabling and integrated electrical distribution systems that reduce weight and enhance the efficiency of EV architecture. The company also continues to evolve its modular "Smart Vehicle Architecture" to meet increasing demand from global automakers for scalable, intelligent platforms.

BorgWarner has unveiled its HVH320 electric motor, capable of producing up to 400 kW of peak power, which is already being integrated into commercial EV applications. Additionally, the company is advancing its dual inverter technology to improve drivetrain efficiency and reduce thermal losses.

Marelli, a global Tier-One with strong roots in both Japan and Italy, is rapidly expanding its e-Axle systems, which combine motor, inverter, and transmission in a compact unit. Marelli recently announced a major partnership with a European OEM to supply these systems for premium electric sedans launching in 2026.

Hitachi Astemo is focusing on integrated powertrain solutions for EVs and hybrids. The company is scaling up its EV-specific brake-by-wire systems and compact traction inverters. By 2026, Hitachi aims to triple its global EV component output, targeting both Japanese and global OEMs.

Hyundai Mobis is also aligning its product roadmap with electrification goals. In addition to power modules and battery packs, Mobis is developing wireless BMS systems and autonomous-ready platforms that combine LiDAR sensors, in-wheel motors, and AI-based safety software.

These comprehensive shifts underscore the industry's recognition that EVs are not simply a new propulsion system, but a complete overhaul of vehicle architecture. Tier-One suppliers that successfully pivot their portfolios to offer high-efficiency, modular, and software-integrated solutions will play a central role in shaping the next generation of mobility.

Strategic Acquisitions and Joint Ventures

Tier-One suppliers recognize that time is of the essence. Instead of building new capabilities from scratch, many are accelerating their transition through acquisitions and strategic alliances. These moves provide immediate access to advanced technologies, reduce development timelines, and enable deeper integration into OEM EV platforms.

In 2024, ZF Friedrichshafen acquired Aeva's lidar unit, providing immediate access to next-generation sensor technology critical for autonomous EVs. The acquisition also strengthens ZF's position in advanced perception systems used in Level 3 and Level 4 autonomous driving.

Aisin Seiki has formed a high-profile collaboration with Thailand’s state-backed EV initiative to develop thermal management systems customized for tropical environments. This regional partnership reflects a growing trend among Japanese suppliers to deepen ties in Southeast Asia, where EV adoption is accelerating due to government incentives and infrastructure investments.

In a major move within the North American market, BorgWarner announced the acquisition of Santroll’s eMotor business in early 2025. The deal enhances BorgWarner’s capabilities in integrated drive modules and aligns with its Charging Forward 2027 strategy, which aims to derive over 45% of revenue from electrified products.

Meanwhile, Dana Incorporated has partnered with Israeli startup REE Automotive to co-develop flat, scalable EV chassis systems. These skateboard platforms support various vehicle classes, from last-mile delivery vans to passenger EVs, offering OEMs a plug-and-play solution that reduces design and engineering time.

In Europe, Valeo entered a joint development program with STMicroelectronics to co-design next-generation automotive silicon carbide (SiC) power modules. These components are critical for improving the efficiency of electric drivetrains, especially in premium and high-performance vehicles.

Hyundai Mobis has invested in Silicon Valley-based lidar company Luminar to jointly develop advanced autonomous driving features for the global EV market. This partnership is aimed at enhancing Mobis' competitiveness in ADAS and long-range sensor systems.

Continental, through its subsidiary Elektrobit, is collaborating with Google Cloud to offer high-performance, cloud-connected automotive software platforms that can be continuously updated over the air. The partnership highlights the convergence between automotive and tech industries, especially as vehicles become more software-defined.

Bosch has also expanded its footprint through a joint venture with China's Qingling Motors to produce commercial electric trucks. The venture allows Bosch to gain deeper insights into the Chinese market while leveraging Qingling's local manufacturing capabilities.

These collaborations not only help suppliers acquire cutting-edge technologies, but they also support regional localization, accelerate time-to-market, and reduce capital expenditure. As the EV landscape grows more complex, Tier-One suppliers are forming ecosystems—not just contracts—that redefine how value is created and delivered across the industry.

Localizing the EV Supply Chain

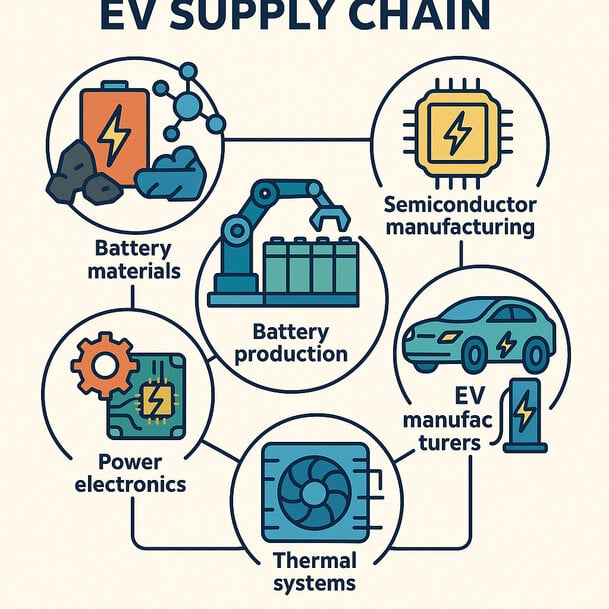

The EV revolution has exposed vulnerabilities in the global supply chain, particularly around critical battery minerals such as lithium, cobalt, and nickel. With increasing geopolitical tensions, trade barriers, and export restrictions from key supplier countries like China, the Democratic Republic of Congo, and Indonesia, Tier-One suppliers are actively localizing their production and sourcing strategies to ensure continuity and resilience.

Denso has significantly expanded its EV component manufacturing footprint in Southeast Asia. With new production facilities in Indonesia and Vietnam, the company is not only tapping into cost advantages but also positioning itself as a regional supply hub for the growing ASEAN EV market. These facilities focus on producing battery management systems, power modules, and thermal components, which are essential for local and export EV platforms.

Hyundai Mobis has begun localizing EV module production in India, supported by government incentives under the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme. The facility will manufacture battery packs and drive control systems, contributing to India's ambition to become a global EV export base.

Continental has expanded its footprint in Mexico, opening a new plant in San Luis Potosí to produce high-voltage inverters and sensor modules. The plant is strategically positioned to serve North American OEMs including GM and Ford, who are increasingly sourcing components from the USMCA region to reduce dependency on East Asian supply chains.

Japanese Tier-One supplier Nidec has launched a major investment program in Poland and Hungary to produce e-axles and electric drive systems for European automakers. These investments are backed by EU funding aimed at enhancing the region's EV value chain independence, particularly from Chinese imports.

In China, Bosch has ramped up its joint ventures with local battery producers and is investing in rare-earth recycling facilities to ensure long-term material availability. These localized approaches also enable Bosch to comply with China's domestic content requirements and benefit from subsidies offered for locally made EV components.

Meanwhile, American suppliers like BorgWarner and Dana are increasingly investing in the U.S. Midwest and Southern states to build out battery pack assembly and thermal system production, leveraging Inflation Reduction Act (IRA) incentives that favor North American manufacturing.

OEMs like Hyundai, Toyota, and BYD are demanding that suppliers provide regional support to avoid disruptions caused by cross-border logistics bottlenecks. This shift is fueling growth in new EV manufacturing corridors including Mexico, Thailand, India, Eastern Europe, and the southern United States—regions where governments are aggressively courting investment with tax breaks, expedited permits, and infrastructure grants.

Localization is no longer a cost-driven strategy; it is a necessity in the era of electric mobility. It enhances flexibility, strengthens supply chain resilience, and ensures that Tier-One suppliers can meet the evolving regulatory, environmental, and market demands of the EV ecosystem.

Software and Electronics Integration

The automotive world is becoming more software-defined with every passing year. From battery control systems to infotainment and ADAS, software now represents a significant portion of a vehicle’s value. Tier-One suppliers are responding by evolving into software-first organizations.

Continental spun off its software division to operate as an independent business unit focused on developing embedded systems and cloud integration. Valeo, another major player, is investing heavily in centralized domain controllers and over-the-air (OTA) update platforms that enable real-time software enhancements post-purchase.

One of the most notable advancements came at CES 2025, where LG Magna e-Powertrain unveiled an AI-driven e-drive system that optimizes energy consumption based on real-time traffic data, weather, and user behavior. This convergence of AI and electrification is reshaping how suppliers approach design, engineering, and service delivery.

Embracing Smart Manufacturing

To meet the changing demands of OEMs and improve production agility, Tier-One suppliers are adopting smart manufacturing technologies. The days of rigid assembly lines and batch manufacturing are giving way to flexible, data-driven production environments that can quickly adapt to changing vehicle specifications.

Atlas Copco’s Smart Integrated Assembly platform provides a blueprint for such transformation. The system includes assembly tools, software, and services that create fully connected production environments. Capabilities such as automated torque control, MES integration, and real-time data analytics allow suppliers to reduce waste, lower energy use, and deliver consistent quality at scale.

In addition, Atlas Copco’s automation solutions—including turnkey robot cells and vision inspection systems—enable Tier-Ones to scale production efficiently while meeting the high traceability requirements of global OEMs. The company also supports cobot integration, enhancing assembly line flexibility while optimizing labor utilization.

Navigating Platform Proliferation

The shift to EVs has introduced a paradox: while vehicle architectures are becoming more software-defined and modular, the number of distinct EV platforms is rising. By 2028, over 200 individual automotive platforms will exist globally, up 117% from 2020, according to Oliver Wyman.

While automakers are consolidating R&D efforts into fewer platforms to boost volume efficiency, the customization demands from consumers and regional regulations are creating fragmentation. Tier-One suppliers must therefore adopt a modular product strategy that enables mass customization. Platform-agnostic solutions—such as scalable battery enclosures, modular e-axles, and adaptable thermal systems—are in high demand.

Suppliers that can offer plug-and-play components compatible with multiple OEM platforms will capture greater market share while reducing costs through economies of scale.

The Economics of Transition: Short-Term Pain vs. Long-Term Gain

Adapting to EVs comes with a steep financial curve. Suppliers must continue servicing ICE programs—many of which remain profitable—while investing heavily in electrification. Balancing short-term profitability with long-term positioning is a delicate dance.

The shift also exposes suppliers to volatility in raw material costs. Metals such as lithium and cobalt have experienced dramatic price swings, and suppliers often lack the pricing power to pass these costs on. Consequently, long-term contracts, vertical integration with raw material suppliers, and advanced forecasting systems are becoming essential tools.

Bosch, for instance, is securing long-term cobalt supply through strategic partnerships with mining firms and has begun hedging commodity prices to protect margins. These risk mitigation strategies will become increasingly important as material shortages and geopolitical risks continue to challenge the global EV supply chain.

The Control Tug-of-War: OEMs vs. Suppliers

The evolving EV landscape is also redrawing the boundaries between OEMs and Tier-One suppliers. Where OEMs once relied on suppliers for full-system solutions, they are now building in-house capabilities to control the software stack, battery development, and even semiconductor design.

This desire for control is leading to a reconfiguration of supplier-OEM relationships. Some suppliers are doubling down on proprietary ecosystems, while others, such as ZF and NXP, are adopting an integration-friendly approach. The latter are developing flexible, standards-based platforms that make it easier for OEMs to plug their technologies into existing architectures without vendor lock-in.

This strategic repositioning is essential, as OEMs increasingly prioritize supply chain control, faster innovation cycles, and cost optimization.

Failures and Lessons: What Not to Do

Not all Tier-One transitions have been smooth. Aptiv’s 2022 acquisition of software firm Wind River is a cautionary tale. While the acquisition was touted as a move into cloud-native platforms, integration challenges and a lack of software monetization led to a sharp decline in investor confidence. As of early 2025, Aptiv’s stock has dropped by more than 50% from pre-acquisition highs.

Similarly, Bosch and Continental have had to enact significant layoffs and cost-cutting measures. Bosch’s plan to eliminate over 5,000 jobs and reduce hours at key EV-component plants is indicative of the financial strain involved in transformation. The key takeaway: strategic alignment, execution capability, and operational integration matter just as much as acquisition size.

Stop Selling Parts, Start Selling Outcomes

For decades, Tier-One suppliers thrived by perfecting components. In the new EV landscape, however, OEMs are no longer looking for individual parts—they want integrated solutions that solve real problems.

This means suppliers must shift from an engineering-centric mindset to an outcome-oriented approach. Companies like Harman and Bosch have made this leap by delivering platforms, not just products. Harman has evolved from a stereo and infotainment supplier into a connected vehicle enabler offering OTA software, cybersecurity, and cloud-based diagnostics.

Bosch, too, now positions itself as a mobility provider, offering everything from fleet management to smart charging and ADAS solutions. These capabilities turn Bosch from a component supplier into a strategic partner, deeply embedded in the OEM’s value chain.

The Road Ahead: Three Strategic Options

Tier-One suppliers now face three strategic paths as the automotive industry rapidly transitions to electrification, software-defined vehicles, and regionalized production models. Each path presents unique risks and opportunities, and the decisions made today will determine whether suppliers remain central to the mobility ecosystem or are marginalized in the years to come.

1. Integration Partner: The most promising and sustainable route is to become a collaborative, integration-focused partner to OEMs. These suppliers provide modular, interoperable systems that plug seamlessly into multiple vehicle platforms, accelerating time to market and reducing complexity for OEMs. Integration partners embrace open standards, offer co-development capabilities, and support over-the-air updates and lifecycle service integration. Companies like ZF, Bosch, and NXP are already exemplifying this model by working closely with automakers to develop intelligent systems that support autonomy, connectivity, and electrification. These suppliers don’t just ship components—they solve problems, support flexibility, and deliver innovation as a service.

2. Proprietary Ecosystem Builder: This route involves doubling down on exclusive technologies and vertically integrated systems in an attempt to lock OEMs into specific supplier ecosystems. While this strategy worked in previous decades—where high investment in mechanical systems created dependency—the software-driven nature of modern vehicles makes it less viable today. OEMs are increasingly wary of vendor lock-in and are instead investing in internal software teams and open-source platforms to maintain control. Suppliers that insist on proprietary stacks may be perceived as restrictive and inflexible, leading to marginalization. Aptiv’s Wind River acquisition and its struggles to monetize a tightly integrated software suite serve as a cautionary tale for those pursuing this path without a clear execution roadmap.

3. Commodity Supplier: The least desirable path is to remain a supplier of undifferentiated, low-margin components. These suppliers’ risk being replaced by lower-cost Tier-Two or offshore vendors as OEMs seek aggressive cost reductions. As electrification reduces mechanical complexity, the perceived value of basic components diminishes, unless paired with smart data, traceability, or platform integration. Commodity suppliers also have little influence over design or product roadmap decisions, making them reactive rather than strategic. This path is marked by shrinking margins, diminishing market share, and eventual obsolescence in an industry driven by platform consolidation and rapid innovation.

The most successful Tier-Ones will be those that understand their new role in a decentralized, software-defined, sustainability-driven industry. They will not only supply parts but co-create value alongside OEMs. This requires shifting mindsets from engineering deliverables to business outcomes, and from transactional relationships to long-term, strategic partnerships. In the future, the real differentiator won't be just what you build, but how well you integrate, adapt, and elevate the OEM's brand and experience.

Conclusion: Reinvention or Irrelevance

The global auto industry is undergoing its most dramatic transformation in over a century. Electrification, software dominance, and new consumer expectations are redefining mobility. For Tier-One suppliers, this is a moment of reinvention—one that demands courage, capital, and a long-term commitment to structural change.

Survival depends on more than innovation—it demands strategic vision, operational agility, and a willingness to redefine long-standing business models. It requires investment in talent, reengineering of product lines, and a culture that welcomes disruption rather than fears it. The suppliers that embrace this change will become indispensable partners in the next era of mobility. Those that cling to the past will be left behind as OEMs bring more functions in-house or forge direct partnerships with agile tech startups.

As the world accelerates toward a 50/50 mix of ICE and EVs by 2030, Tier-One suppliers are no longer just linkages in the value chain. They are now key architects of a new automotive future—one built on digital ecosystems, sustainable manufacturing, and intelligent, connected vehicles. Their influence will not only be measured by the parts they produce but by the outcomes they enable: cleaner air, safer roads, and smarter transportation networks.

The road ahead is clear: evolve or exit. For Tier-Ones willing to lead, this transition marks not an end, but the beginning of their most impactful era yet.